- HJEM

- Produkter

- Industrier og applikationer

- OM

- KONTAKTE

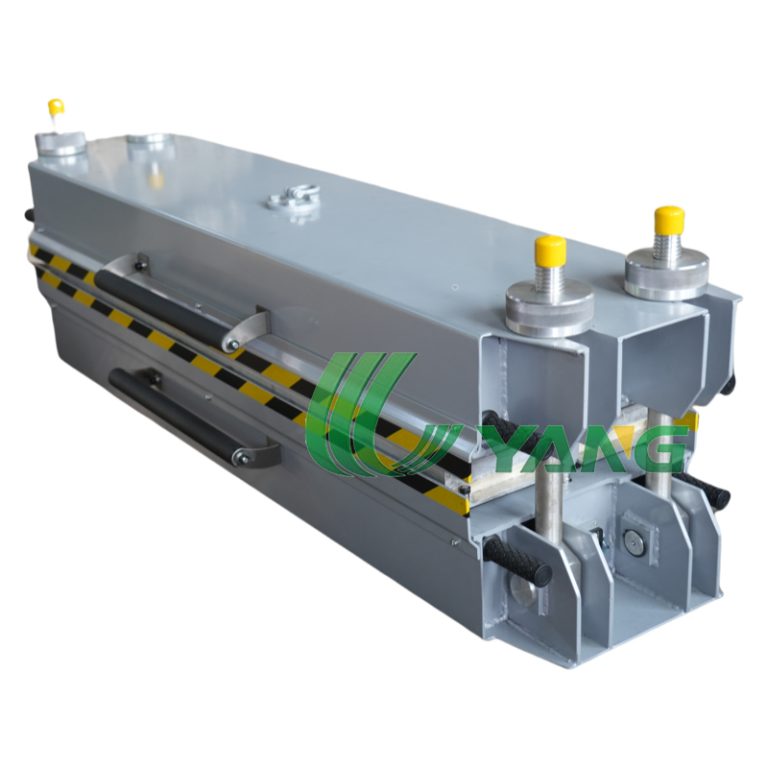

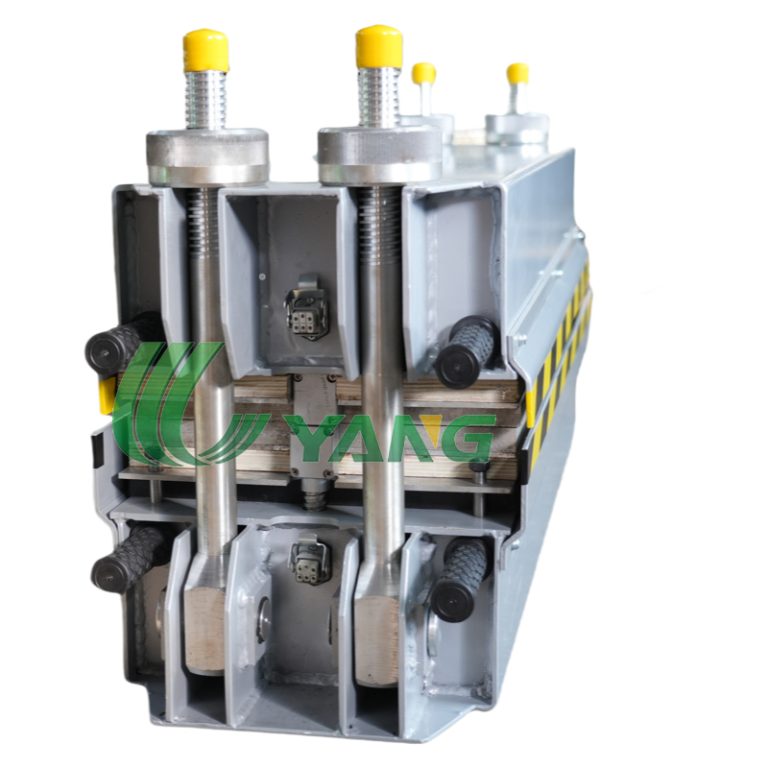

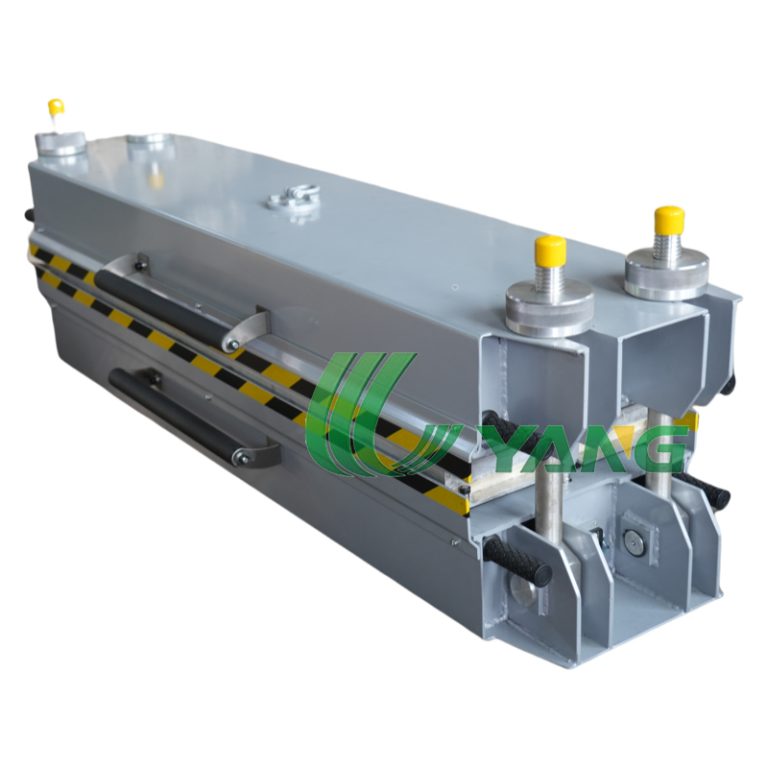

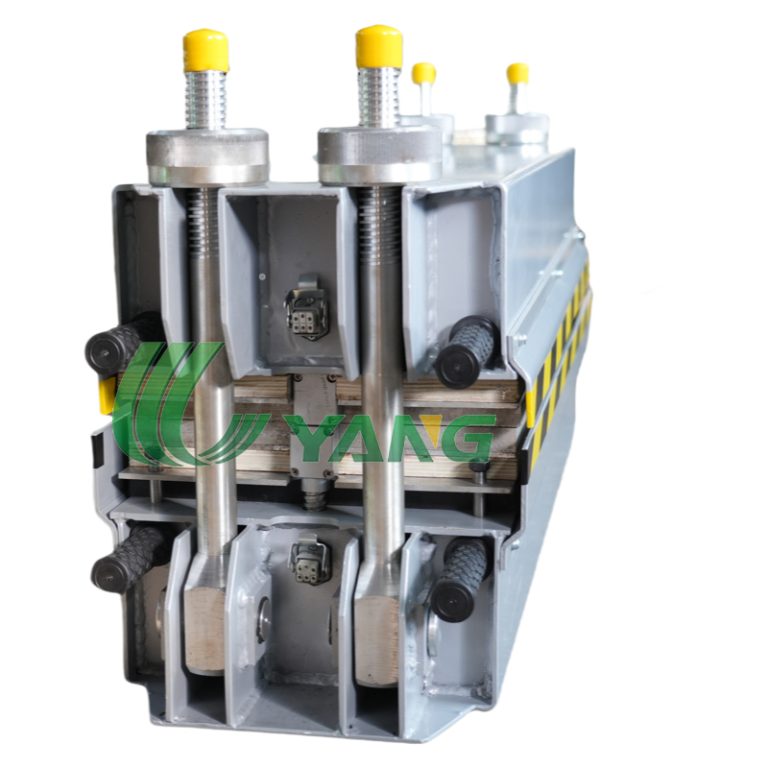

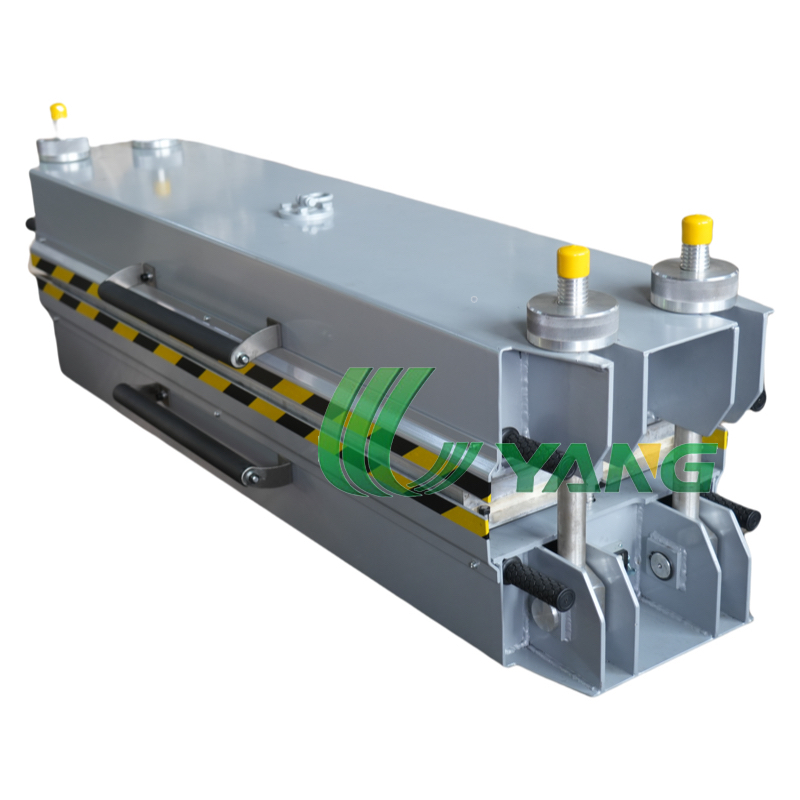

The PRO Series 100 is a lightweight aluminum-frame vulcanizing press designed for fast, efficient splicing. Featuring end handles and positioning rings (on larger models), it is easy to handle and accurately position at the splice site

The PRO Series 100 is a lightweight aluminum-frame vulcanizing press designed for fast, efficient splicing. Featuring end handles and positioning rings (on larger models), it is easy to handle and accurately position at the splice site

Consistent & Even Pressure

Efficient Cooling System

Precise Temperature Control

Modular & Scalable

Durable & Field-Ready

Optional Advanced Heating

PRO Series Vulcanizing Press – Fast, Reliable, On-Site Belt Splicing

Professional Equipment for Gummi transportbånd Repair and Maintenance

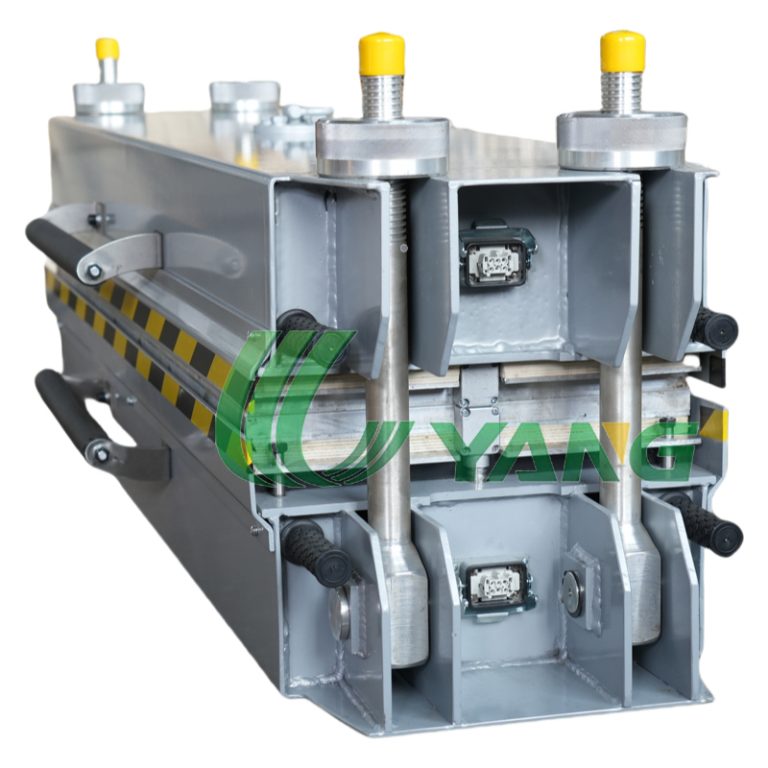

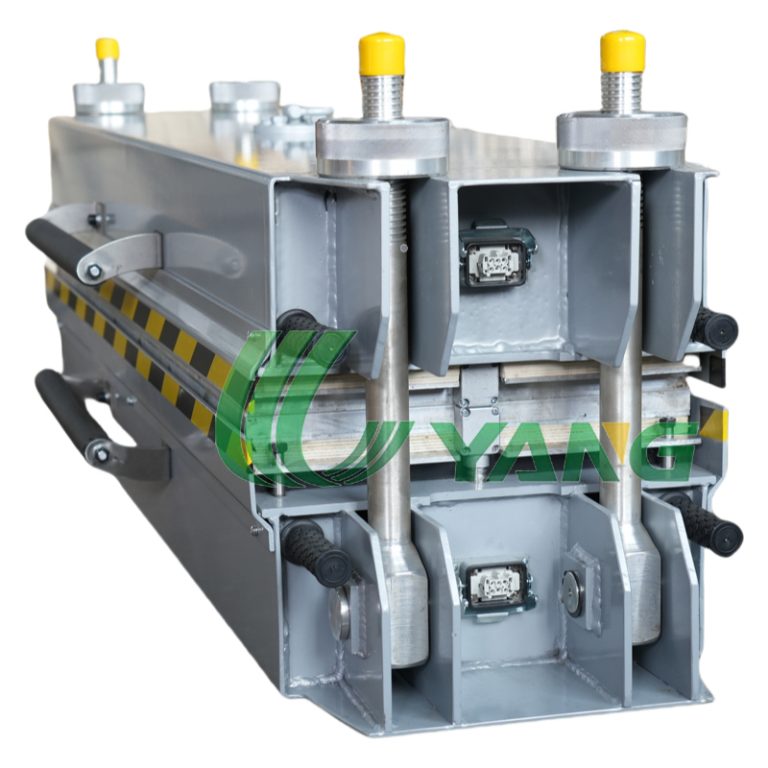

The PRO Series Vulcanizing Press is engineered for fast, preciseog uniform splicing of rubber conveyor belts—ideal for mining, cement, logistics, and heavy-duty material handling industries.

Crafted med en durable all-aluminum frame, the PRO Series is lightweight yet powerful. With user-friendly end handles and positioning rings (for larger models), this press ensures easy setup and smooth operation in field environments.

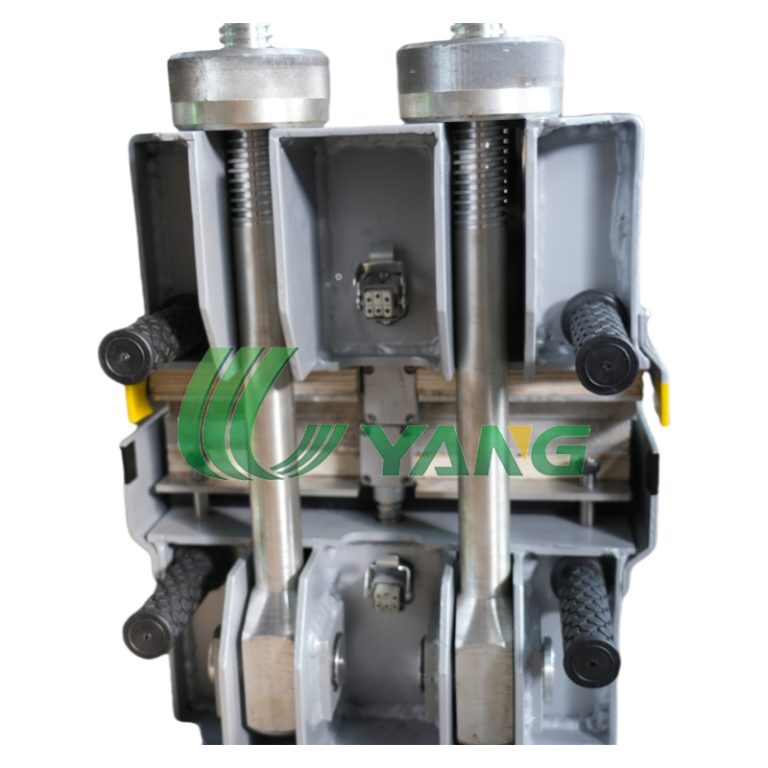

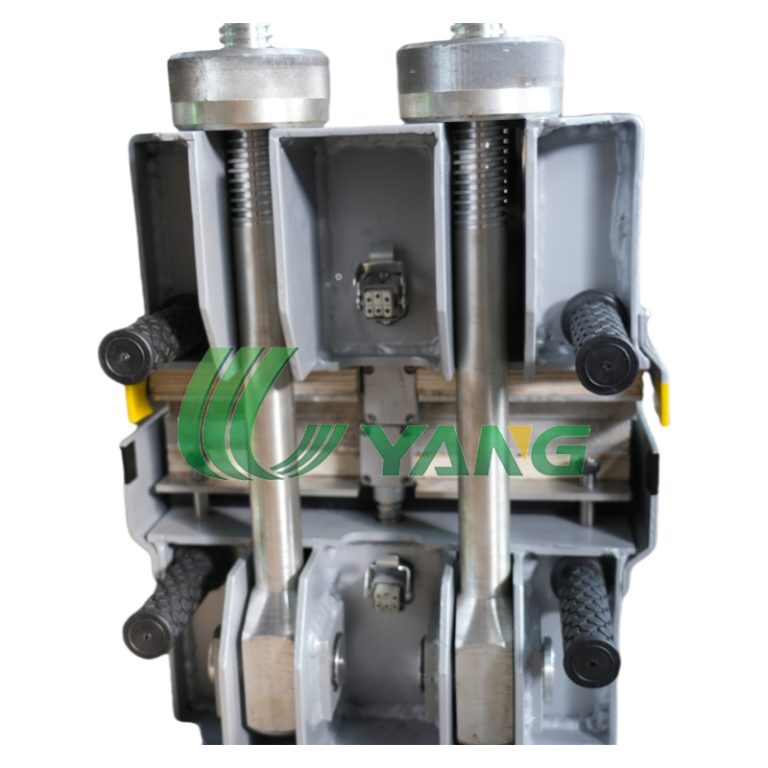

Uniform Pressure: “Pressure Bag” system guarantees consistent pressure across the splice.

Fast Cooling: Built-in cooling system shortens downtime between splices.

Efficient Heating: Optional “Silicone Element” provides stable and even heat distribution.

Præcisionskontrol: E4P-RS control panel enables accurate temperature and timing settings.

Portable & Durable: Upper and lower aluminum frames for lightweight portability.

Customizable Sizes: Standard and made-to-order options available.

Long Splice Support: Side-by-side setup accommodates extended splice lengths.

Whether in the workshop or on-site, the PRO Series delivers performance you can trust—designed by UYANG, a trusted name in vulcanizing solutions.

| UY– 100PSI –Rectangular Models | ||||||||

| Model –UY – 100 PSI | Maximum operating pressure 100 PSI (7 kg/cm )

Maximum temperature 325 deg F (160 deg C) |

|||||||

| Model

|

Heating Plate size (mm)

|

Width of the belt (mm)

|

Total Weight(kgs)

|

Overall height

(mm)

|

Overall

width (mm)

|

Overall

length (mm)

|

Equipment | |

| pump

|

control box | |||||||

| UY1858-TW | 455*1475 | 1350 | 290 | 520 | 530 | 1980 | 1 | 1 |

| UY1864-TW

|

455×1625 | 1500 | 317 | 590 | 505 | 2125 | 1 | 1 |

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

. depositum: 30% depositum før masseproduktion.

. Produktion arrangeret: Vi behandler produktionen.

. Resterende betaling: Efter inspektion, saldo før afsendelse.

. Forsendelse: Vi sender varerne til destinationsporten.

. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;