- HJEM

- Produkter

- Industrier og applikationer

- OM

- KONTAKTE

DA

DA

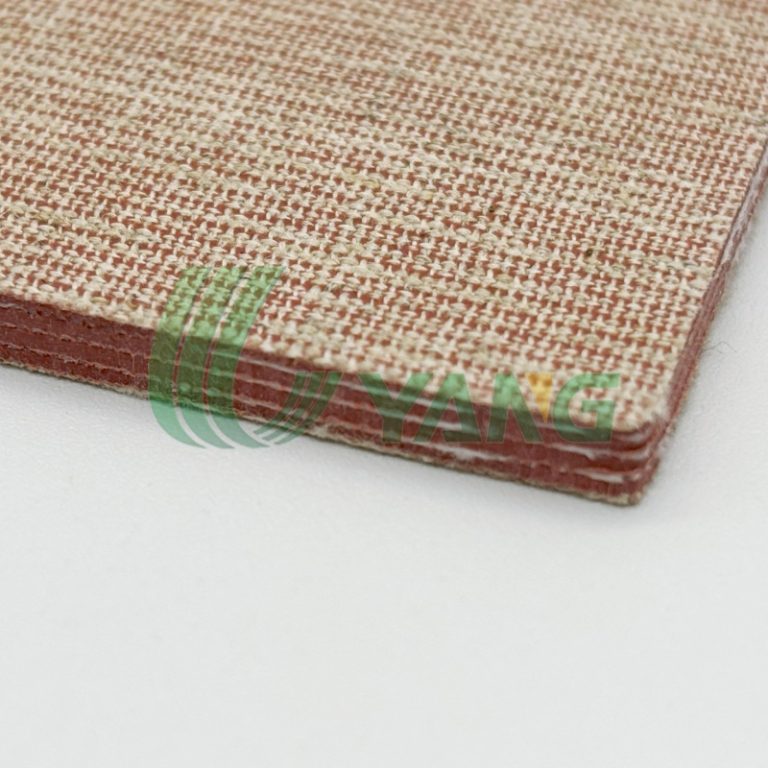

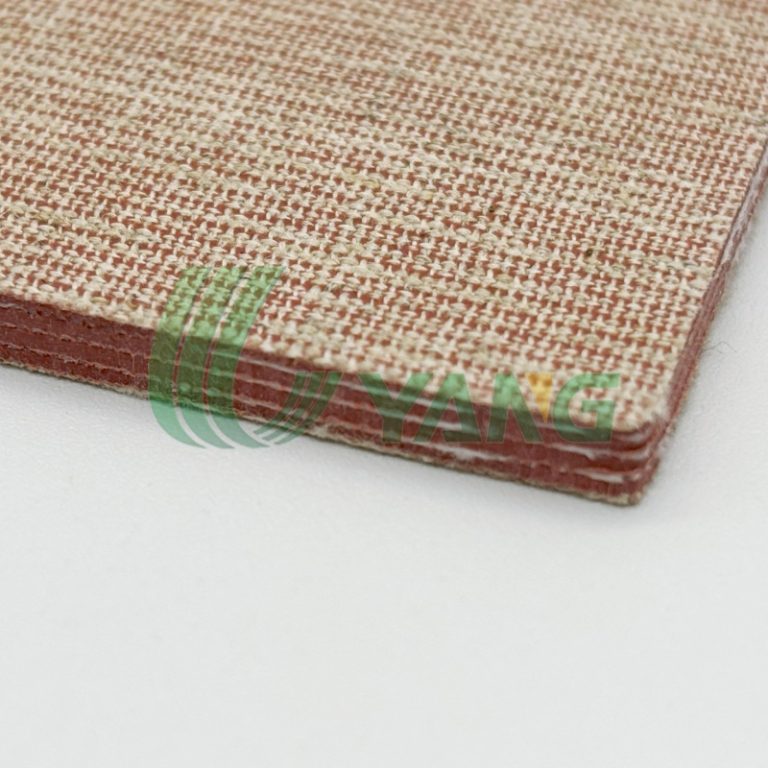

UYANG BELTING Tobacco Nitrile Rubber Belt is specially developed for the tobacco processing industry, with strict cleanliness, anti-static, and non-contaminating requirements of tobacco handling environments, and exceptional dimensional stability, durability, and precise tracking — even under long-term continuous operation. The surface pattern and rubber formula can be tailored to prevent tobacco product adhesion and reduce dust accumulation.

UYANG BELTING Tobacco Nitrile Rubber Belt is specially developed for the tobacco processing industry, with strict cleanliness, anti-static, and non-contaminating requirements of tobacco handling environments, and exceptional dimensional stability, durability, and precise tracking — even under long-term continuous operation. The surface pattern and rubber formula can be tailored to prevent tobacco product adhesion and reduce dust accumulation.

Tobacco Leaf Handling & Processing

Cigarette Production & Packaging Lines

Cut Tobacco Conveying

Drying, Blending, and Storage Lines

| Item | Details |

|---|---|

| Materiale | Natural Rubber |

| Struktur | 5 Ply Fabric / 4 Rubber Layers |

| Tykkelse | 4,0 mm |

| Overfladetekstur | Stof |

| Funktioner | Anti-static, wear-resistant, low noise, non-toxic, |

| Industry Focus | Mainly used in Primary processing of tobacco leaves; |

✅ Non-Toxic

✅ 5 Ply Fabric Reinforcement

Provides high tensile strength and minimal elongation, ideal for continuous and high-speed conveying systems.

✅ 4-Layer Rubber Coating

Ensures excellent surface grip and wear resistance, while maintaining flexibility over pulleys and curves.

✅ Anti-Dust & Clean Surface Design

Reduces tobacco dust retention, ensuring clean material transport and easy maintenance.

✅ Customizable Surface Texture

Can be finished with smooth, fine fabric, or anti-slip embossing to suit specific stages of tobacco processing.

✅ Stable Tracking & Long Service Life

Engineered for low noise, minimal slippageog consistent performance, even in humid or temperature-variable environments.

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

1. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

2. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

3. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

4. depositum: 30% depositum før masseproduktion.

5. Produktion arrangeret: Vi behandler produktionen.

6. Resterende betaling: Efter inspektion, saldo før afsendelse.

7. Forsendelse: Vi sender varerne til destinationsporten.

8. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;