- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

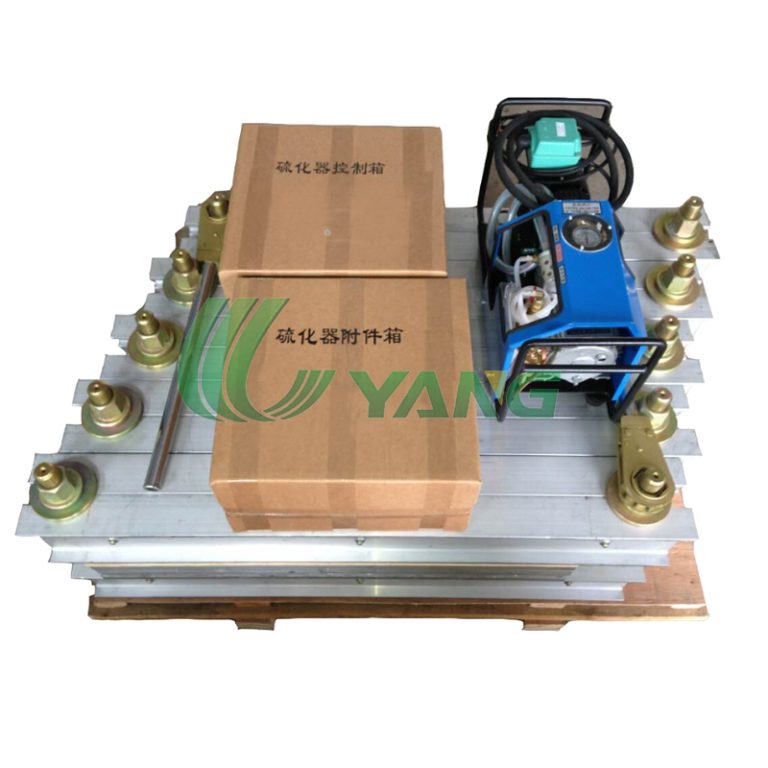

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

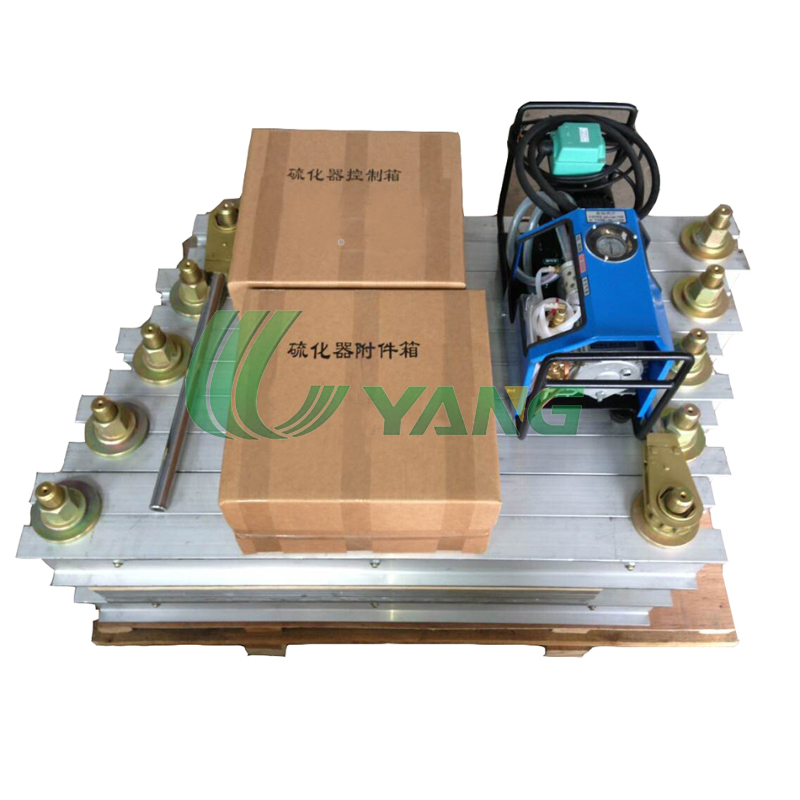

Portable Design – Compact and lightweight for easy transport and setup.

Uniform Heating – Ensures consistent vulcanization across the splice area.

Even Pressure – Stable pressure system (0–1.5 MPa) for strong, reliable joints.

Easy Operation – Plug-and-play control cabinet with integrated cables.

Wide Application – Suitable for various belt types and heavy industries.

Reliable On-Site Splicing for All Types of Rubber Belts

The UYCBV Conveyor Belt Vulcanizer is a versatile, field-ready vulcanizing press designed for high-efficiency splicing of rubber conveyor belts. Compact in size and lightweight for easy transport and installation, the UYCBV is ideal for on-site maintenance and emergency repairs.

Equipped with a uniform heating system and well-distributed pressure (0–1.5 MPa), this press ensures strong, durable belt joints. The integrated control cabinet and multi-core plug system allow for safe, stable, and efficient operation—with minimal maintenance.

Technical Parameters

Lightweight and portable for easy on-site setup

Uniform temperature and pressure for high joint quality

Automatic control cabinet with plug-and-play cable system

Suitable for canvas, nylon, steel cord, and heat/chemical-resistant belts

Widely used in mining, metallurgy, power plants, ports, cement, and more

Non-explosive and corrosion-safe environments only

Why It Matters:

The quality of a belt splice directly impacts conveyor performance and belt lifespan—especially for long-distance and high-strength systems. The UYCBV Vulcanizing Press is an essential tool for ensuring reliable, high-performance belt joints.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;