Homogeneous conveyor belts, made from seamless TPU/TPE, offer unmatched hygiene and durability for food, pharmaceutical, and medical industries. This guide explores their benefits, selection criteria, and implementation for optimal performance in demanding environments.

Introduction

What Are Homogeneous Conveyor Belts?

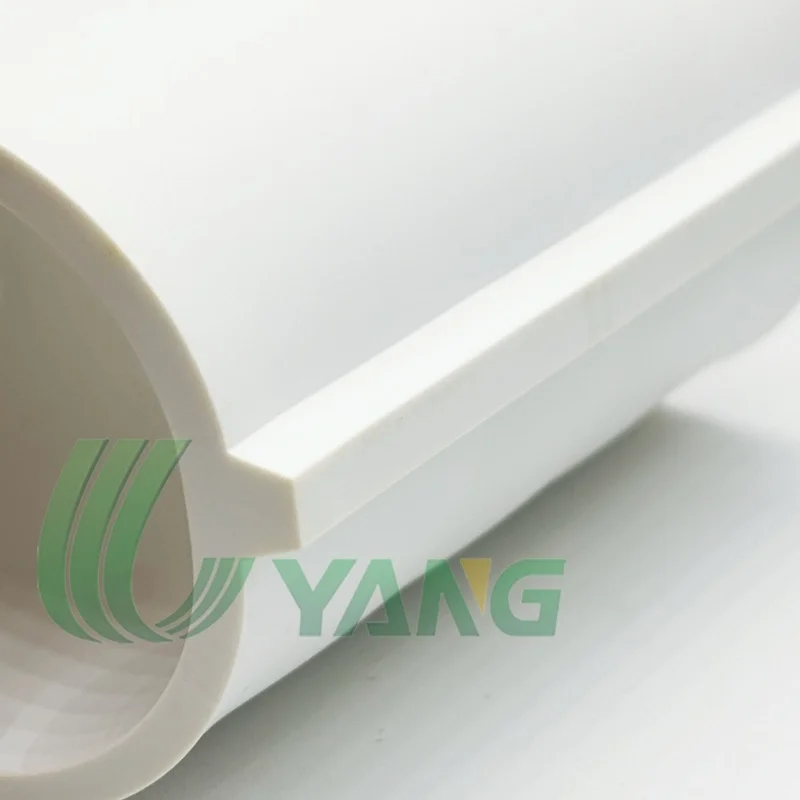

Homogeneous conveyor belts, made from a single thermoplastic material such as TPU (thermoplastic polyurethane) or TPE (thermoplastic elastomer), these have no seams, layers, or fibers. They’re super smooth and keep germs away. This makes them awesome for places that need to stay super clean, like food factories, medicine labs, or hospitals.

Why Are Homogeneous Conveyor Belts Super Important?

Today’s factories need belts that can handle tough cleaning, like high-pressure sprays, chemical wipes, or hot steam. Homogeneous conveyor belts are perfect for this. They’re super clean, tough, and easy to wash. Their one-piece design stops problems like peeling or fraying, which old belts get. This cuts down on breaks and keeps work running smoothly.

Checking Your Factory’s Needs

What You Move and Where You Work

Picking a homogeneous conveyor belt starts with knowing what you’re moving. Oily meats, sticky dough, or wet fish need belts that don’t soak up water or grease but still grip well. Think about your workplace too. Cold rooms, wet air, or hot cleaning sprays can affect belts. You need one that stays strong in those spots.

How Much You Move and How It’s Set Up

How much stuff you move each day and how fast your lines go matters. This decides belt thickness, surface feel, and how much weight it can hold. Big, busy factories need belts that don’t stretch or sag. The belt’s width, drive style, and slope angles gotta match your machines to stop slipping or wobbling.

Looking at Materials and Belt Builds

One-Piece Plastic vs Old Fabric Belts

Old conveyor belts have layers, like a fabric middle for strength and a plastic top. But these layers can split when wet, chemical-soaked, or stressed. Homogeneous conveyor belts are one solid chunk. No seams or joins mean no spots for germs to hide or parts to break.

Why TPU and TPE Are Awesome

TPU (thermoplastic polyurethane) and TPE (thermoplastic elastomer) are top picks for homogeneous conveyor belts. They fight off oil, cuts, water damage, and germs super well. They’re bendy too, so they work on tiny wheels or twisty paths. Uyang Belting uses fancy European TPU to make sure belts are safe and work great in clean places.

Keeping Things Super Clean

No Spots for Germs to Hide

The slick, non-soaky surface of homogeneous conveyor belts stops food bits or liquids from sticking. That’s where germs love to grow. With no fabric inside and sealed edges, these belts don’t suck up gunk. They meet HACCP and GMP clean rules, so they’re safe for food.

Faster Cleaning, Less Waiting

Homogeneous conveyor belts clean up quick with CIP machines, steam, or hot water sprays. They handle strong cleaning chemicals without getting hurt. Uyang Belting’s belts can cut cleaning time by half. This saves money on workers and keeps your factory running longer.

Checking Tracking and Drive Stuff

Why Positive Drive Belts Rock

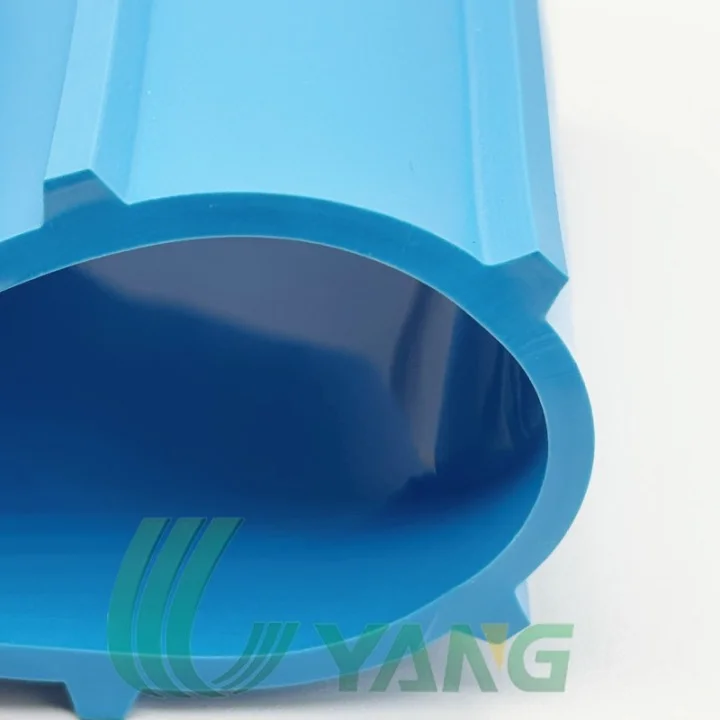

Positive drive belts use teeth that lock with sprockets, not just friction. This keeps the belt on track and stops slipping. It’s super key for keeping products spaced right and avoiding messes in auto setups. Uyang Belting makes belts with built-in drive teeth that fit standard sprockets perfectly.

Making Sure It Fits Your Setup

If you’re swapping out old belts or upgrading, homogeneous conveyor belts can get custom extras like center guides, side walls, or drive bumps. Keeping belts lined up and tight makes them last longer. It also saves your machines from extra wear.

Toughness and Saving Money Long-Term

Super Strong Against Wear

Homogeneous conveyor belts are built to handle factory stress. They fight off scratches, bumps, and sharp edges. Unlike layered belts, they don’t fray at the sides or peel apart. This means they don’t break down early like old belts.

Cheaper in the Long Run

Homogeneous conveyor belts might cost more upfront. But they last way longer and need less fixing. With fewer swaps and less stopping, your factory stays busy. This keeps products clean and top-notch while saving cash.

Following Rules and Getting Certified

Meeting World Safety Rules

Homogeneous conveyor belts gotta follow global food safety rules. Uyang Belting’s belts are certified by FDA, EU 10/2011, and ISO 9001:2015. They also meet ATEX and EN/ISO 340 for no-static and fire-safe stuff. These stamps mean the belts are safe for food and work great in strict spots.

Ready for Checks and Paperwork

Uyang Belting gives full proof papers with their belts. You can ask for tracking reports too. This makes passing safety checks easy. It shows clients, partners, and food inspectors you’re doing things right.

Custom Stuff for Special Jobs

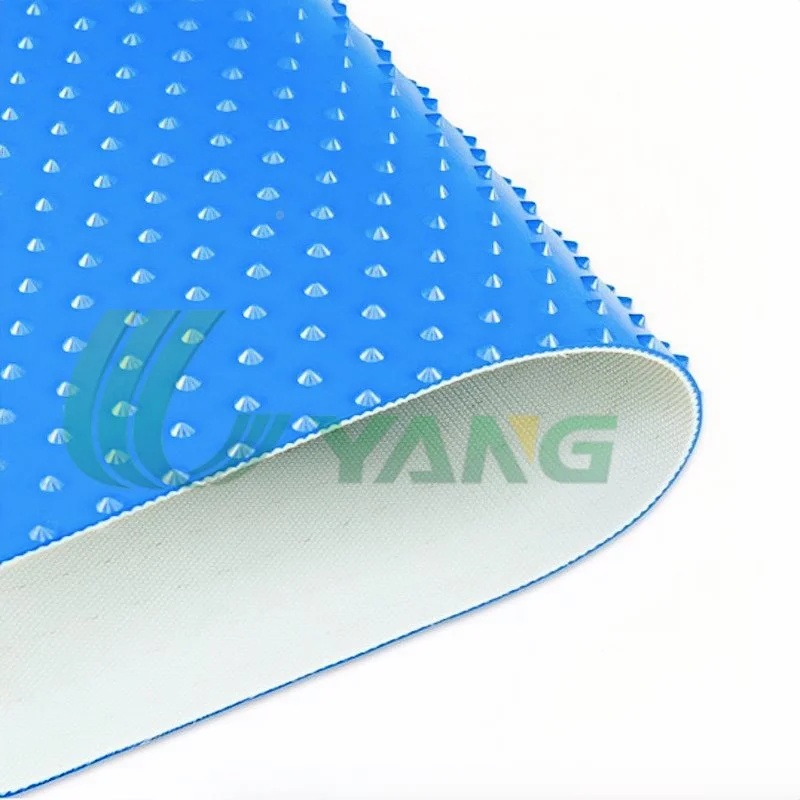

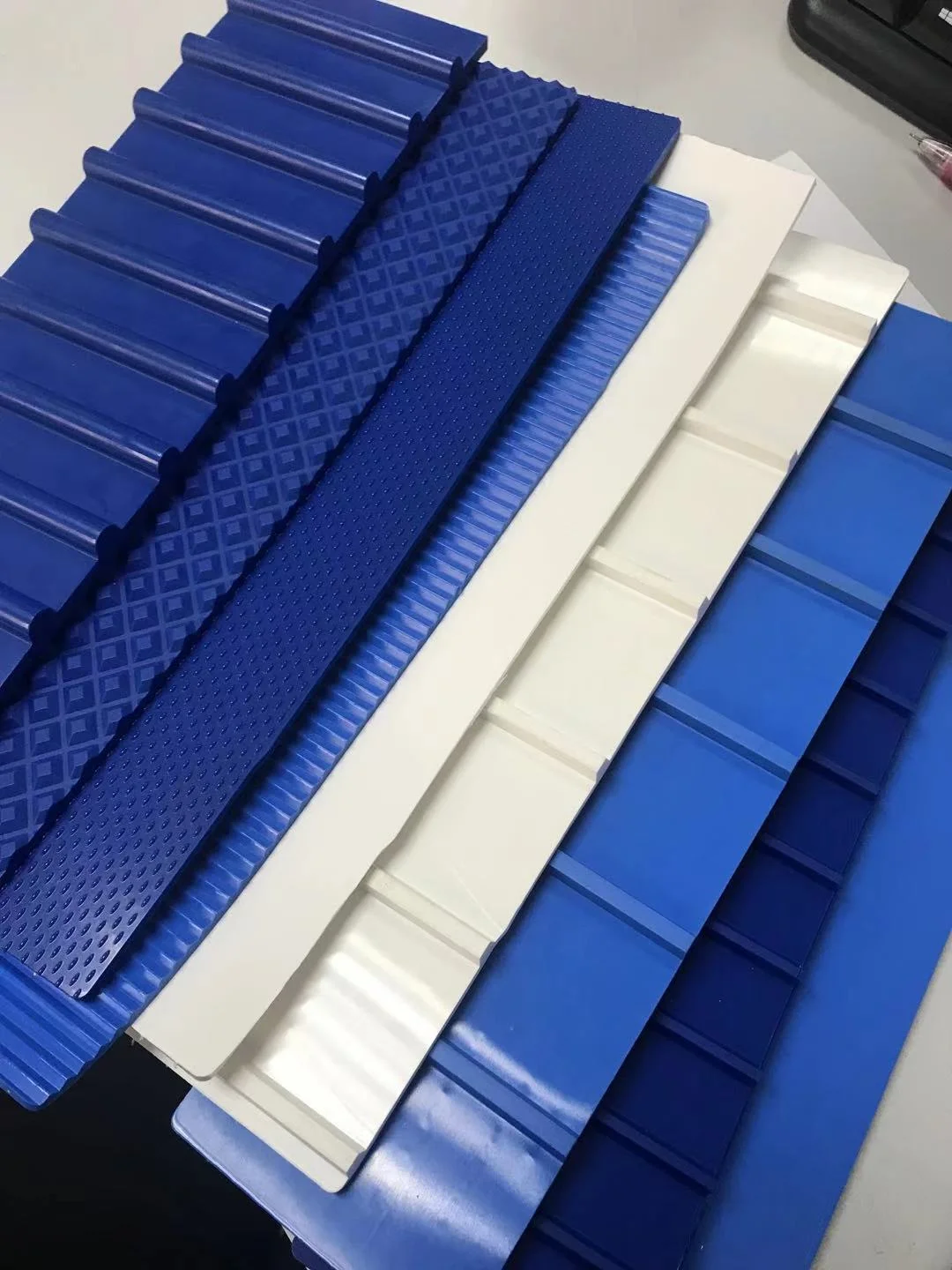

Cool Design Options

Uyang Belting has tons of ways to make homogeneous conveyor belts just for you. Pick different thicknesses, surface feels (like smooth, ribbed, or bumpy), or clean colors like blue to spot dirt easy. They also do sealed edges, holes, ridges, or side walls.

Fitting Weird Work Needs

Got sharp tools, lots of washdowns, or sticky, fragile stuff? Uyang Belting can make belts with the perfect surface and material mix. Their team works with you to build belts that fit your exact factory setup.

Picking a Great Supplier

Why Help and Reach Matter

A smart, quick supplier makes using homogeneous conveyor belts easy. Uyang Belting helps with teams that speak lots of languages, fast price quotes, and fix-it help by video or phone. Their belts go to over 50 countries. They have got a big after-sale team to back you up.

Quick Delivery and Custom Orders

Uyang Belting’s huge 80,000-square-meter factory has 15 fancy production lines. They can send belts fast, even custom ones. They take OEM/ODM orders and give free samples. This lets you test belts before buying a bunch.

Wrap-Up and Tips

Picking the Best Belt

Choosing the right homogeneous conveyor belt means looking at your factory’s clean needs, work amount, product kinds, and machine setups. Uyang Belting’s belts nail it in all these spots. They mix super clean, tough, and money-saving awesomeness.

Next Steps to Get Started

If you’re thinking about switching to homogeneous conveyor belts, talk to experts first to figure out what you need. Ask for samples, check rule papers, and test drive fits. These steps make sure you get a cleaner, trustier belt system.

Extra Tips for Picking Your Belt

When picking a homogeneous conveyor belt, think about your job. Sticky dough or fragile stuff loves smooth belts. Oily meats or wet fish need grippy textures. For super busy lines, go for thick, strong belts. Uyang Belting can tweak belts for your machines, like adding side walls for slopes or teeth for perfect tracking. Always check if belts match FDA or EU rules for food safety. A quick call to UYANG’s team can clear up any questions and get you the perfect belt fast.

Why Uyang Belting Shines

Uyang Belting isn’t just about making belts—they make factories better. Their homogeneous conveyor belts are tested like crazy to be super clean and tough. They use top-notch TPU from Europe and follow strict world rules. Plus, they’re speedy at making custom belts for any job. Whether you’re moving food, pills, or medical gear, Uyang Belting has the know-how to make your work shine.

FAQs

Q1: Can homogeneous conveyor belts handle hot steam or water cleaning?

A: Yes! Uyang Belting’s homogeneous conveyor belts are built for steam cleaning and hot water sprays. They won’t warp or break down.

Q2: Are seamless belts harder to put on than old ones?

A: No! Uyang Belting gives training and heat-weld tools. These make putting on belts quick and clean with no long stops.

Q3: How do I know if I need a smooth or bumpy surface for my stuff?

A: Smooth belts are great for sticky or soft stuff like dough. Bumpy ones grip better for oily or wet things like meat or fish. Uyang Belting can pick the best surface for your job.