- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

HE

HE

Producing high-quality tires demands advanced technology, precise equipment, and skilled professionals, as well as excellent supplier partnerships.

In collaboration with our customers and top research organizations, we have created a comprehensive line of belting solutions specifically designed for the tire manufacturing sector.

Featuring our distinctive range of fabric-based Process & Conveyor Belts, along with Modular Belts, UYANG BELTING delivers superior technical belting solutions for every stage of tire production.

Producing high-quality tires demands advanced technology, precise equipment, and skilled professionals, as well as excellent supplier partnerships.

In collaboration with our customers and top research organizations, we have created a comprehensive line of belting solutions specifically designed for the tire manufacturing sector.

Featuring our distinctive range of fabric-based Process & Conveyor Belts, along with Modular Belts, UYANG BELTING delivers superior technical belting solutions for every stage of tire production.

Typical Applications:

• Tire carcass/tread forming lines

• Green tire conveying systems before vulcanization

• Automated warehousing and handling

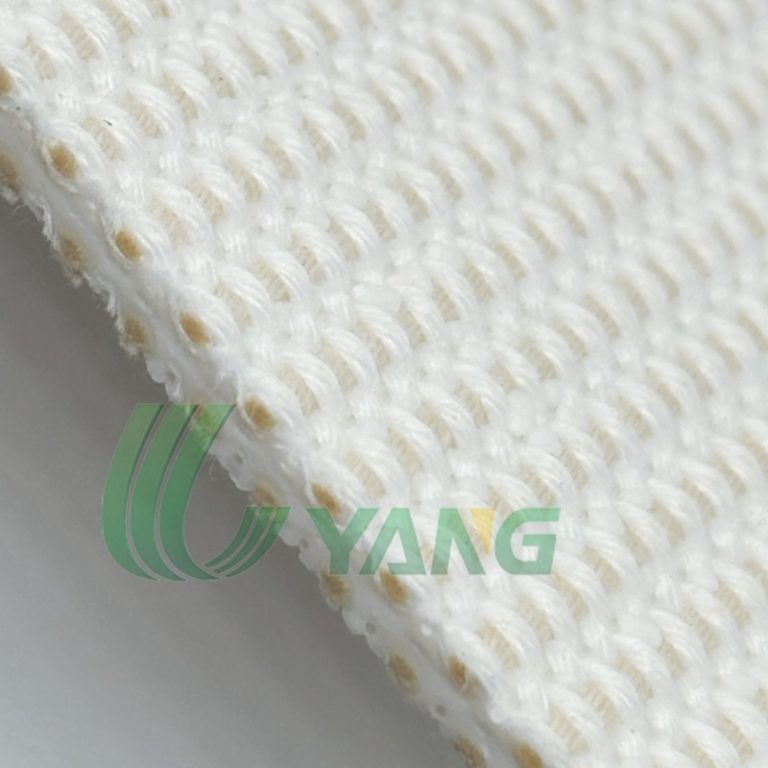

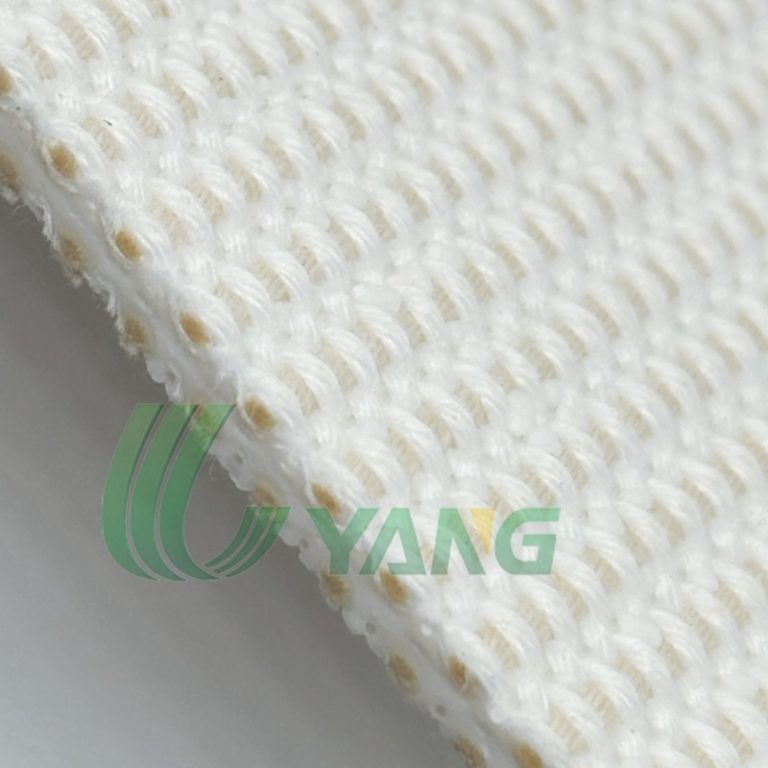

The Extra Latitudinal Cotton Canvas TPU conveyor Belt is an innovative solution ,expecially engineered for tire manufacturing procession. Mixed high-elasticity TPU (Thermoplastic Polyurethane) with a unique Extra Latitudinal Cotton Canvas structure, there are good abrasion resistance, impact absorption, and flexibility—ideal for precision conveying and forming processes in tire production.

Key Benefits:

✔ High Strength & Wear Resistance – The TPU surface provides superior tear resistance and chemical corrosion protection, extending service life.

✔ 3D Cotton Cushioning Design – The three-dimensional cotton layer effectively absorbs vibrations, protecting tire components from damage during transport.

✔ Anti-Slip Precision – Customized surface textures prevent slippage, ensuring stable and accurate positioning of tire materials.

✔ Lightweight & Easy Maintenance – Lighter than traditional rubber belts, reducing energy consumption while enabling quick cleaning and replacement.

| Item | Details |

|---|---|

| צֶבַע | White |

| Material | Extra Latitudinal Cotton Canvas and TPU |

| Top Surface | Extra Latitudinal Cotton Canvas |

| Middle Part | White TPU |

| Bottom Surface | Extra Latitudinal Cotton Canvas |

| Structure | 2 Ply Fabric / 1 TPU Layers |

| Total Thickness | 2.5 mm |

| Key Features | Double-sided cotton, durable |

| Application Focus | Tires industry, Textiles, packaging, light conveying |

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;