- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

HE

HE

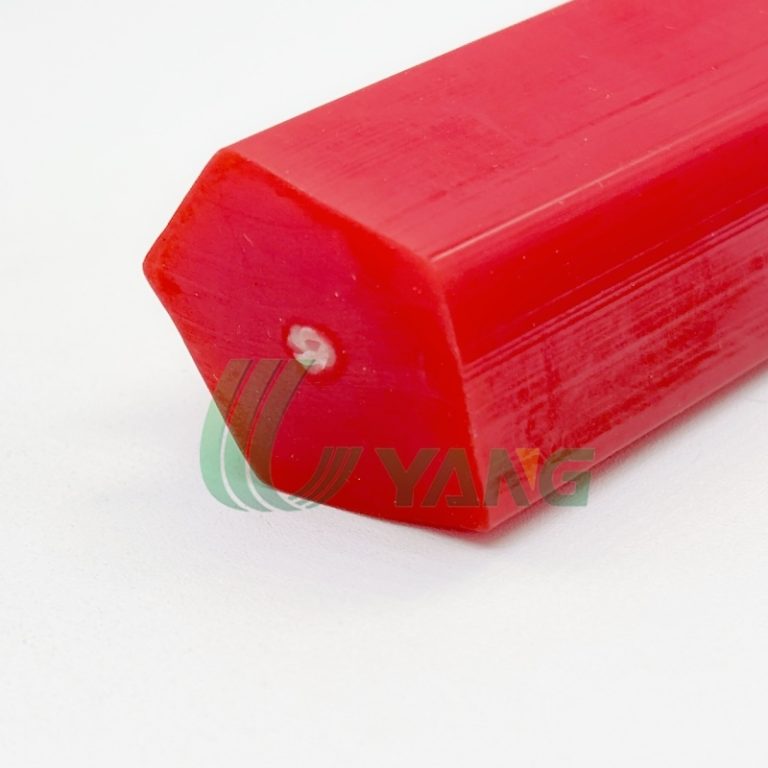

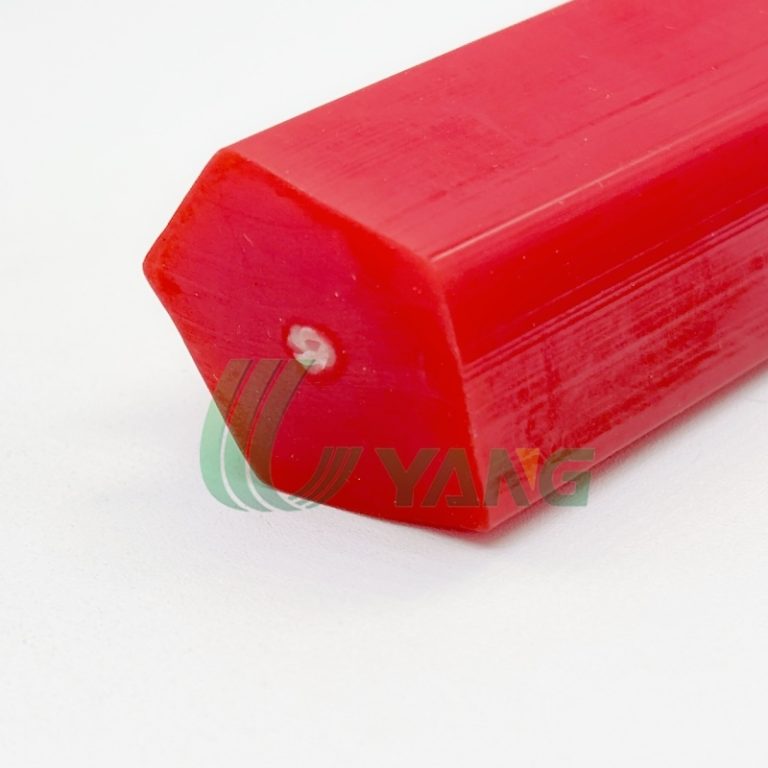

UYANG’s Kevlar Reinforced Thermoweldable Ridge-top Belts combine aramid fiber reinforcement with raised ridge profiles to deliver superior strength while minimizing product contact – ideal for fragile material handling in tile, glass, and wood industries.

UYANG’s Kevlar Reinforced Thermoweldable Ridge-top Belts combine aramid fiber reinforcement with raised ridge profiles to deliver superior strength while minimizing product contact – ideal for fragile material handling in tile, glass, and wood industries.

Superior Load Capacity

Aramid fiber core delivers 1800N/mm² tensile strength

<0.5% elongation under heavy loads, eliminating slippage

Product Protection Specialist

Unique 5-ridge profile design

Reduces product contact by 60%

Ideal for fragile items (tiles/glass)

Precision Power Transmission

Ridge-guided tracking prevents misalignment

3x longer lifespan than standard pentagonal belts

Extreme Environment Ready

Temperature range: -30℃ to 100℃

Optional anti-static/FDA-compliant versions

Product Structure:

Anti-Contact Design:

Unique pentagonal profile with raised ridges

Reduces product contact by 60% vs standard belts

Reinforced Core:

Aramid fiber tensile cords (1800N/mm² strength)

Prevents elongation (<0.5%) under heavy loads

Durable Composition:

Homogeneous polyurethane/polyester construction

Optional abrasion-resistant top coating

Key Advantages:

✓ Product Protection: Minimizes surface damage to fragile items (tiles, pottery, wood)

✓ Precision Tracking: Ridge guidance system prevents lateral drift

✓ Heavy-Duty Performance: 3x lifespan compared to conventional ridge-top belts

| Dimensions | Cross section | Approx. weight | Standard roll | Recommended min. pulley ∅ ⌀ | Fmax/belt (standard) | Fmax/belt (overlap) |

|---|---|---|---|---|---|---|

| mm | cm2 | kg/100m | m | mm | kg | kg |

| 17×19 | 2,13 | 25,6 | 30 | 190 | 59 | n/a |

| 22×25 | 3,65 | 43,8 | 30 | 240 | 100,7 | n/a |

Industrial Applications:

• Ceramic tile production lines

• Woodworking CNC transfer systems

• Glass/pottery handling equipment

Technical Specifications:

Temperature range: -30°C to +100°C

Available in FDA-compliant food-grade versions

Custom ridge heights/configurations

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;