Introduction

In the fast-paced world of food processing, the selection of a suitable food-grade conveyor belt plays a critical role in ensuring operational efficiency, regulatory compliance, E food safety. Choosing the wrong belt can lead to contamination, increased downtime, and regulatory penalties. This guide will walk you through the essential considerations for selecting the right food-grade conveyor belt, helping you streamline your production while meeting international hygiene standards.

What Defines a Food-Grade Conveyor Belt?

Hygiene-Centric Design

Food-grade conveyor belts are specifically engineered to prevent contamination and facilitate easy cleaning. Key features include:

- Smooth, non-porous surfaces to avoid bacteria buildup

- Rounded edges and sealed welds to eliminate food traps

- Materials that resist microbial growth

Compliance and Certifications

- Reputable belts comply with international regulations, including:

- FDA (21 CFR 177) for U.S. food contact safety

- EU 10/2011 for European food contact materials

- USDA/3-A Sanitary Standards

- HACCP and GMP alignment for hazard and hygiene control

Uyang Belting ensures all its food-grade belts meet FDA and EU standards, supporting your global compliance efforts.

Key Selection Criteria

Type of Food and Application

The belt material and design should match the type of food being processed:

- Surgelatos: require low-temperature-resistant belts

- Sticky products: need belts with excellent release properties

- Hot or oily items: demand heat- and oil-resistant materials

UYANG’s Cintura di Trasportatore PUs, for example, are ideal for oily and high-moisture food items due to their chemical resistance and easy-to-clean surfaces.

Processing Environment

Environmental factors such as humidity, chemical exposure, E cleaning cycles impact your belt choice:

- High humidity: calls for belts with low water absorption

- Frequent washdowns: demand CIP (Clean-In-Place) compatible designs

- Chemical exposure: requires resistant coatings like TPU or silicone

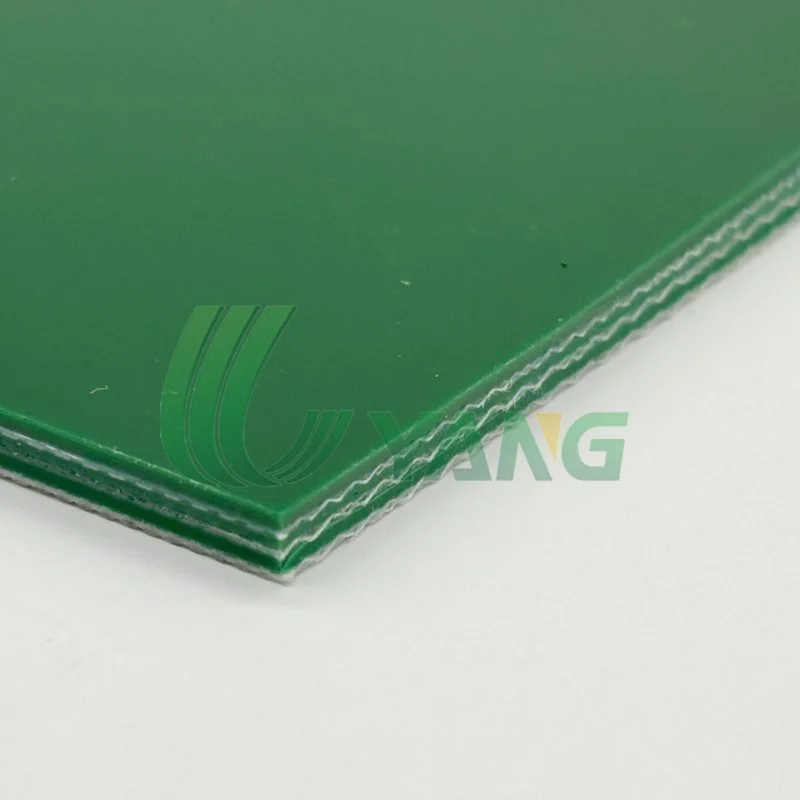

Belt Configuration & Structure

Depending on the conveyor layout, you may require:

- Flat belts for horizontal transport

- Cleated belts for incline applications

- Modular belts for customizable paths

UYANG offers over 200 surface patterns and modular belt options to tailor the solution to your facility’s layout.

Maintenance & Cleanability

Downtime due to maintenance can be costly. Choosing belts with:

- Tool-free disassembly

- Quick-release tensioners

- Integrated hygiene design

UYANG’s homogeneous belts for meat and poultry processing are designed for superior cleanability and fast reassembly.

Durability vs. Cost

Consider the lifecycle cost, not just the initial investment:

- Long-lasting materials like polyurethane or stainless mesh offer better ROI

- High abrasion or chemical resistance extends belt life

UYANG’s belts come con a 12-month quality guarantee and lifetime technical support, minimizing long-term operational risks.

Material Comparison

Stainless Steel Mesh

- Best for high-temperature baking, metal detection, E drying processes

- High durability but heavier and costlier

PVC Belts

- Economical, flexible, E good for dry food handling

- Less resistant to oils and extreme temperatures

PU Belts

- FDA and EU-compliant, resistant to oil, fat, E cleaning chemicals

- Excellent for moist and sticky products

Silicone and TPE

- Withstand high temperatures and aggressive cleaning

- Ideal for bakery, confectionery, E thermo-processing

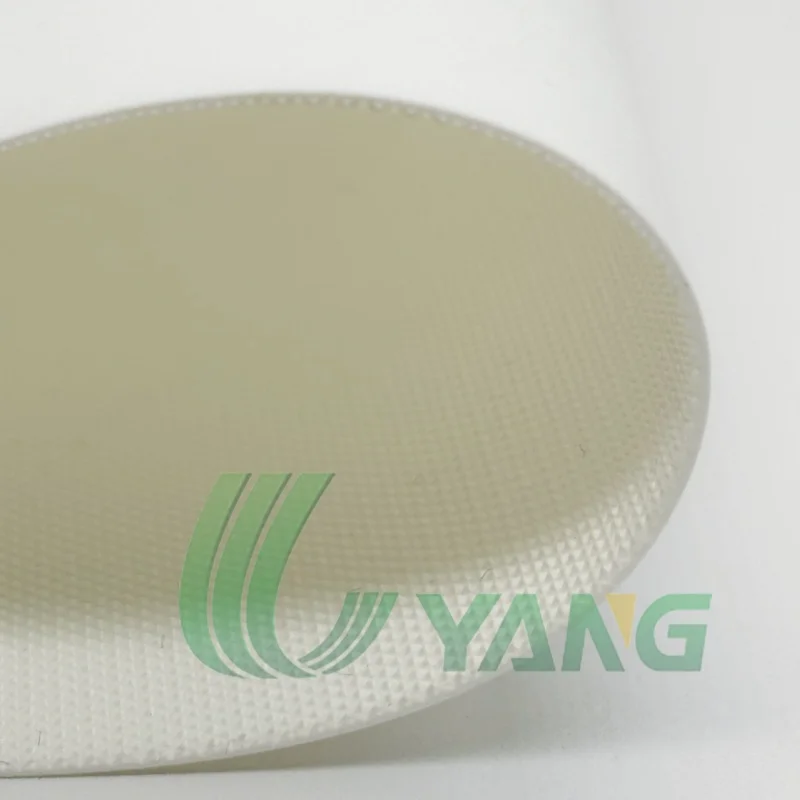

Modular Belts

- Easy to clean and replace sections

- Suitable for applications requiring airflow, drainage, or custom paths

UYANG’s broad portfolio includes all of the above to match your precise application needs.

Accessory Enhancements

Add-On Features

Enhance your belt performance with:

- Sidewalls for spill prevention

- V-guides for self-tracking

- Surface textures for grip or product release

Automation Ready

- Modern food processing requires smart integration:

- Compatibility with metal detectors and vision systems

- Support for inline cleaning systems

UYANG’s belts are engineered for seamless automation integration, reducing manual handling and improving safety.

ROI: Long-Term Value Over Cost

Investment vs. Lifecycle

Initial belt costs should be weighed against:

- Maintenance frequency

- Replacement intervals

- Energy consumption due to friction or belt weight

Partnering with the Right Supplier

Look for:

- Proven industry experience

- Fast lead times and support

- Customization options and technical consulting

Uyang Belting offers OEM/ODM support, multilingual sales teams, E rapid delivery across 50+ countries.

Step-by-Step Selection Guide

- Identify food product characteristics (temperature, moisture, texture)

- Define environmental conditions (washdowns, humidity)

- Evaluate production layout (incline, curves, transfer points)

- Prioritize certifications and compliance requirements

- Consider automation compatibility

- Request sample testing or technical consultation

Conclusion

Choosing the right food-grade conveyor belt requires a comprehensive understanding of your application, hygiene requirements, E operational conditions. Uyang Belting, with over 20 years of experience and a full range of certified solutions, is your trusted partner in optimizing your food production line. From FDA-compliant PU belts to customizable modular systems, our products deliver performance, safety, E efficiency across the global food industry.

FAQ

Q1: What certifications should a food-grade conveyor belt have?

A top-notch food-grade conveyor belt needs to follow big rules like FDA (21 CFR 177) for the U.S. and EU 10/2011 for Europe. Other cool standards include USDA, 3-A Sanitary Standards, HACCP, E GMP. These make sure the belt’s stuff is safe for touching food and keeps things clean for markets all over the world.

Q2: What’s the difference between PU and PVC food conveyor belts?

PU (Polyurethane) belts are super tough against oil, grease, E cleaning stuff. They’re awesome for wet, sticky, or greasy foods. Plus, they’re bendy and easy to clean.

PVC (Polyvinyl Chloride) belts cost less and work great for dry, non-greasy foods. But they’re not as good with hot temperatures or strong cleaners compared to PU.

Q3: How often should food-grade conveyor belts be replaced?

How often you swap out a belt depends on how much you use it, how you clean it, E where it works. Usually, check belts often and replace them every 12–24 months. Do it sooner if you see wear, cracks, or dirt that won’t come off. Uyang Belting gives a 12-month warranty and free tech help forever to keep your belt lasting long.