- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

EN

EN

The air-cooled design eliminates the need for external water or compressed air systems, making the press highly portable and easy to use in any environment. Built-in fans rapidly cool the heating plates after splicing, significantly reducing downtime and increasing work efficiency. This system is especially ideal for on-site service, where mobility, simplicity, and safety are essential. Perfect for workshops and field operations alike.

The air-cooled design eliminates the need for external water or compressed air systems, making the press highly portable and easy to use in any environment. Built-in fans rapidly cool the heating plates after splicing, significantly reducing downtime and increasing work efficiency. This system is especially ideal for on-site service, where mobility, simplicity, and safety are essential. Perfect for workshops and field operations alike.

Key Advantages:

No external cooling required – Built-in air cooling system, ready to use anywhere.

Easy operation – Digital control of temperature and time for precise splicing.

Portable design – Lightweight and compact, ideal for on-site work.

Reliable splice quality – Uniform heating and pressure ensure strong, clean joints.

Versatile use – Designed for PVC/PU belts in logistics, packaging, food, and more.

Air Cooled Splice Press – For PVC/PU Conveyor Belt | UYANG BELTING

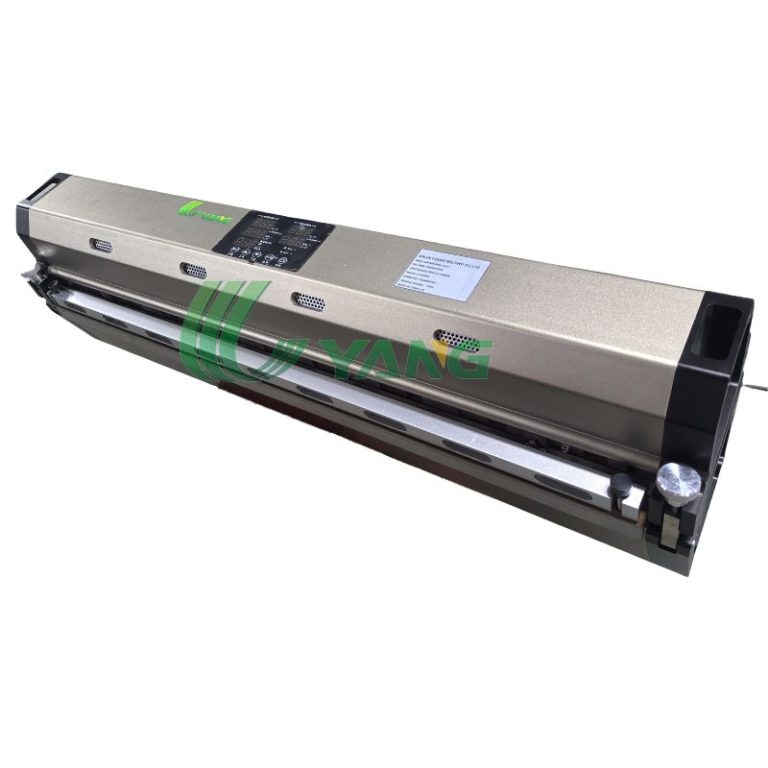

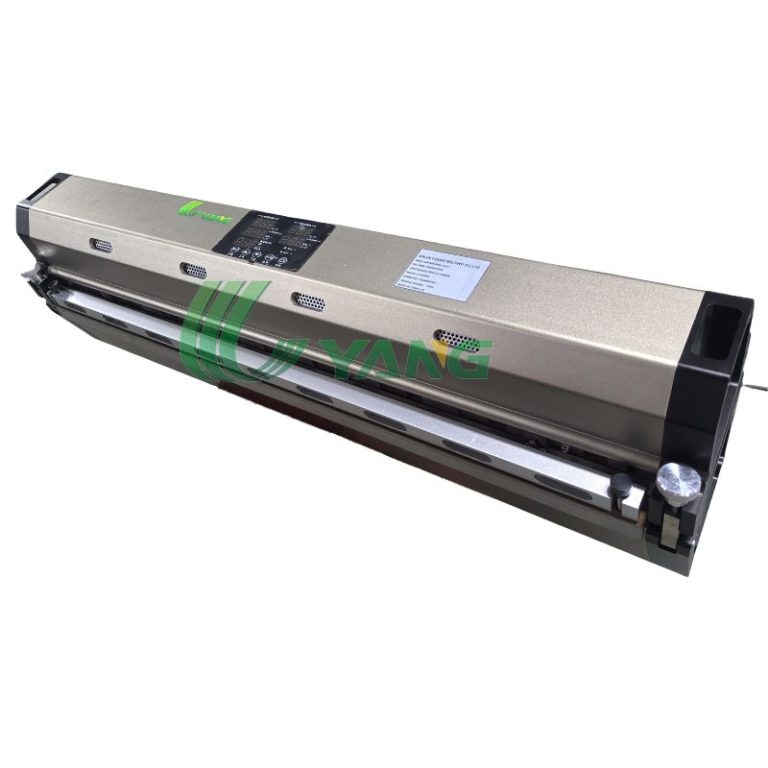

The UYANG Air Cooled Splice Press is a compact and portable splicing solution designed for PVC and PU conveyor belts. With integrated air cooling and digital control, it delivers fast, reliable, and consistent splicing results without the need for external water or air systems.

Key Features:

All-in-one design: Integrated pressure, heating, and cooling systems

Air cooling: No need for external compressors or water cooling

Digital temperature & time control: Precise and easy to operate

Lightweight & portable: Ideal for on-site and workshop use

Suitable for PVC/PU belts: Widely used in logistics, packaging, food, and manufacturing industries

Engineered for speed, efficiency, and ease of use—perfect for maintenance teams and belt service professionals.

Technical data:

| Model | UY300 | UY600 | UY900 | UY1200 | UY1500 | UY1800 | UY2100 |

| Effective length | 385mm/15.2” | 685mm / 27″ | 985mm / 38.8″ | 1285mm / 50.6″ | 1585mm / 62.4″ | 1885mm/74″ | 2185mm/86” |

| Effective width | 130mm / 5.1″ | 130mm / 5.1″ | 130mm / 5.1″ | 130 mm / 5.1″ | 130 mm / 5.1″ | 130 mm /5.1″ | 130 mm / 5.1″ |

| Weight lower part | 16 kg/35.2lbs | 23kg/50.7lbs | 30kg/66.2lbs | 34 kg/75lbs | 41 kg/90.4lbs | 56kg/123.5lbs | 65kg/143.3lbs |

| Weight upper part | 9kg/20lbs | 13kg/28.7lbs | 17kg/37.5lbs | 21 kg/46.3lbs | 26 kg/57.3lbs | 44.2kg/97.4lbs | 51kg/112.4lbs |

| Total weight | 25kg/55.2lbs | 36kg/79.4lbs | 47kg/103.7lbs | 55 kg/121.3lbs | 67 kg/147.7lbs | 100.2kg/220.9lbs | 116kg/255.7lbs |

| Length | 405mm/16″ | 605mm/24″ | 1105mm/43.5″ | 1405mm/55.3″ | 1705mm/67.1″ | 2030mm/79.9″ | 2310mm/90.9″ |

| Overall height | 220mm/8.5″ | 220mm/8.5″ | 220mm/8.5″ | 220mm/8.5″ | 220mm/8.5″ | 330mm/13″ | 330mm/13″ |

| Max. pressure | 2 Bar / 28 PSI | 2 Bar / 28 PSI | 2 Bar / 28 PSI | 2 Bar / 28 PSI | 2 Bar / 28 PSI | 1.83Bar/26.5PSI | 1.83Bar/26.5PSI |

| Max. temperature | 200 ℃/390 ℉ | 200 ℃/ 390 ℉ | 200 ℃/ 390 ℉ | 200 ℃/ 390 ℉ | 200 ℃/ 390 ℉ | 200 ℃/ 390 ℉ | 200 ℃/ 390 ℉ |

| Packaging list

(L x W x H) |

850x450x550mm | 1150x450x550mm | 1450x450x550mm | 1750*450*550mm | 2050*450*550mm | 2350*450*650mm | 2650*450*650mm |

| Gross weight | 53.5 kg | 70.3 kg | 90kg | 105 kg | 122 kg | 169.2kg | 209kg |

Q1: What types of conveyor belts is this press suitable for?

A1: It is specifically designed for thermoplastic belts such as PVC and PU.

Q2: Does it require an external cooling system?

A2: No. The machine features a built-in air cooling system—no need for water or external air compressors.

Q3: Is it easy to carry and operate?

A3: Yes. The press is compact, lightweight, and user-friendly, perfect for on-site and workshop use.

Q4: How long does the splicing process take?

A4: A typical splice, including heating and cooling, takes about 10–15 minutes depending on belt thickness.

Q5: What power supply does it require?

A5: Standard models are available in 220V or 110V single-phase. Custom voltage options are available upon request.

Q6: Can it be used for belts in food-grade applications?

A6: Yes, it is ideal for PU belts used in food processing lines, as it ensures clean and precise joints.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;