- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

EN

EN

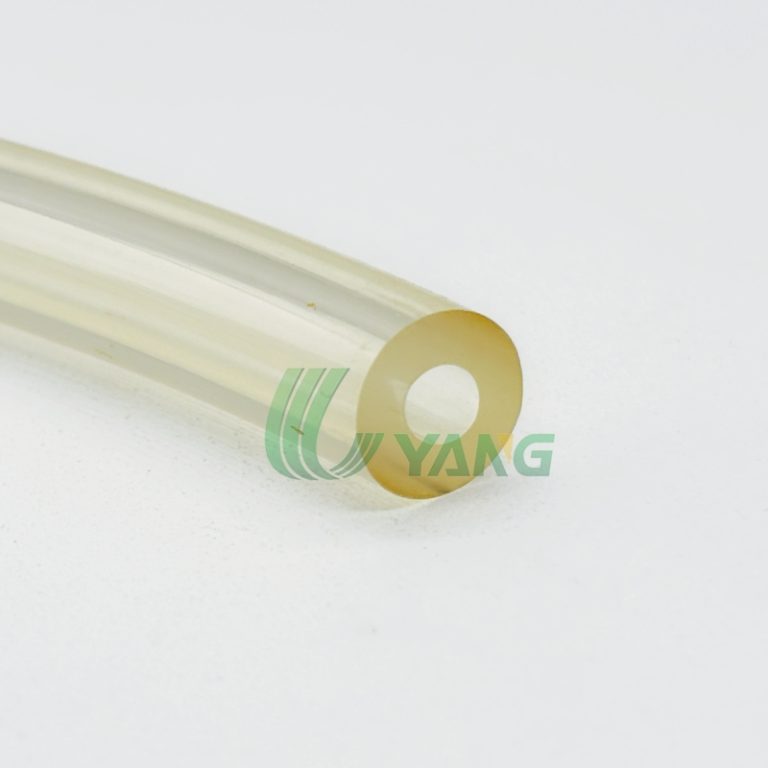

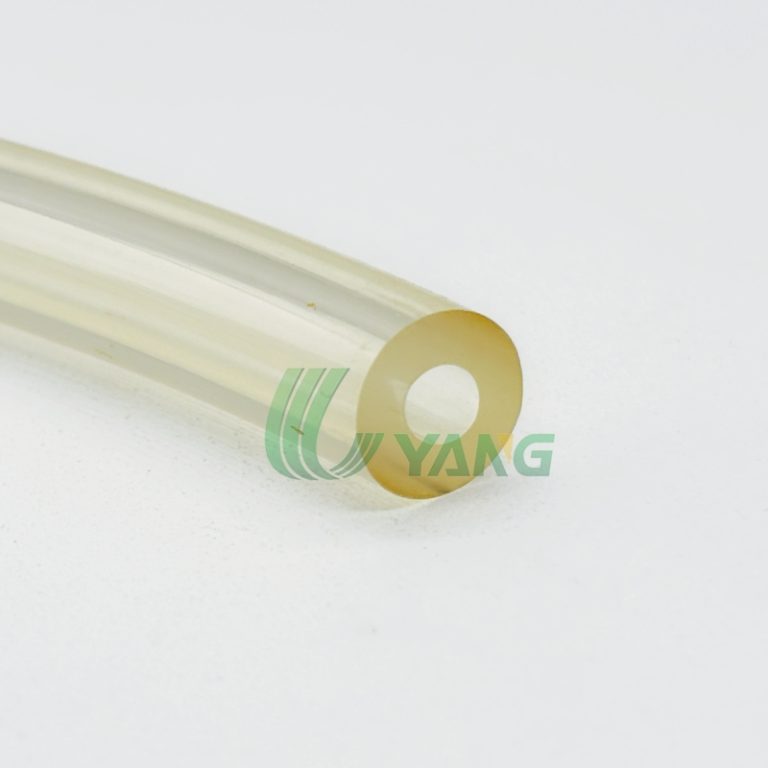

UYANG BELT tubular PU round belt features a unique non-return plug connection system, enabling fast on-site assembly without requiring specialized welding equipment. By inserting the specially designed plug into both ends of the belt, a secure and reliable connection is formed, ideal for frequent disassembly scenarios or emergency repairs. For permanent connections, traditional thermal welding remains fully compatible.

UYANG BELT tubular PU round belt features a unique non-return plug connection system, enabling fast on-site assembly without requiring specialized welding equipment. By inserting the specially designed plug into both ends of the belt, a secure and reliable connection is formed, ideal for frequent disassembly scenarios or emergency repairs. For permanent connections, traditional thermal welding remains fully compatible.

Quick Installation – No special tools required

Exceptional Flexibility – Adapts to dynamic and changing needs

Easy Maintenance – Minimizes downtime and servicing costs

High Performance – Durable and stable operation

Cost-Effective – Reduces overall operational expenses

Equipment Maintenance: Streamlines production line maintenance and reduces downtime

Modular Systems: Perfect for automation equipment requiring quick replacement of conveyor units

Temporary Conveyor Systems: Ideal for exhibition setups or temporary production lines

Food & Pharmaceutical Industries: Supports fast disassembly and cleaning in hygienic environments

Plug connection zone is specially reinforced, capable of withstanding ≥80% of the belt’s original tensile strength

Internal guiding grooves ensure plug lock stability

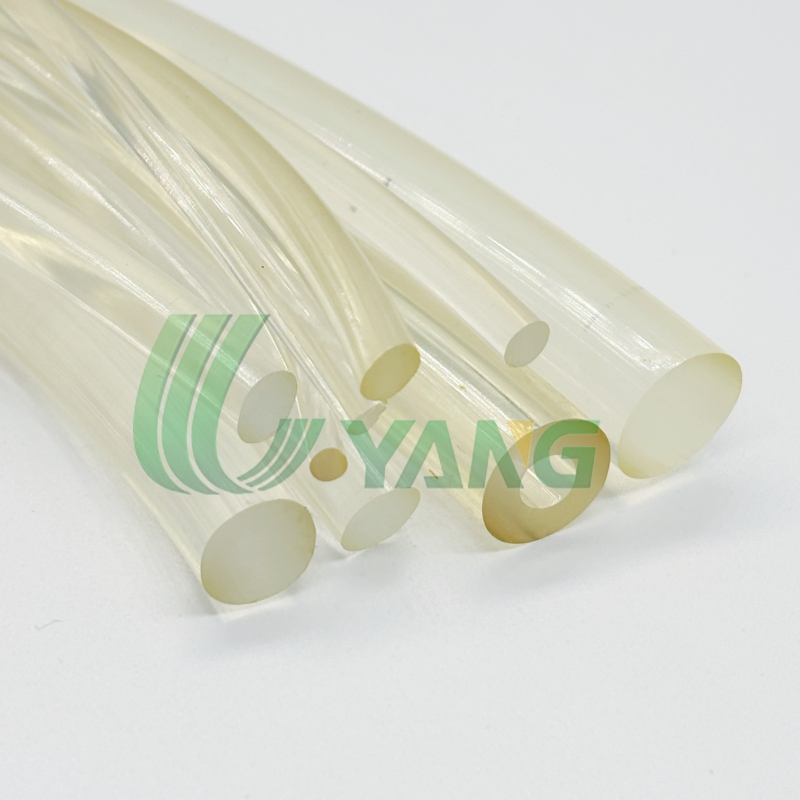

Available in conductive, anti-static, and oil-resistant variants

Extended operating temperature range: -30°C to +80°C

Plug connection is especially recommended in the following scenarios:

✓ Applications requiring disassembly ≥2 times per day

✓ Worksites without professional welding staff

✓ Systems requiring adjustable belt length

Technical Data:

| Size (mm) | Min. pulley dia. (mm) |

Pull force (1%) kg. |

Min. pulley dia. (mm) |

Pull force (1%) kg. |

Min. pulley dia. (mm) |

Pull force (1%) kg. | |

|---|---|---|---|---|---|---|---|

| O.D. | I.D. | ||||||

| 4.8 | 1.8 | 35 | 0.29 | 43 | 0.37 | 45 | 0.68 |

| 6.3 | 2.4 | 45 | 0.49 | 55 | 0.63 | 60 | 1.15 |

| 8 | 3.2 | 55 | 0.78 | 65 | 1.01 | 75 | 1.83 |

| 9.5 | 4 | 65 | 1.10 | 75 | 1.41 | 85 | 2.52 |

| 12.5 | 5.3 | 85 | 1.88 | 100 | 2.42 | 115 | 4.35 |

| 15 | 5.3 | 100 | 2.88 | 120 | 3.71 | 150 | 6.68 |

| 18 | 7.8 | – | – | – | – | 180 | 8.95 |

| 20 | 7.8 | – | – | – | – | 200 | 11.34 |

The latest 3rd generation quick connector incorporates a memory alloy insert, delivering an instant “plug-and-lock” function. Installation time is reduced by 60% compared to traditional methods. Additionally, FDA-approved food-grade materials and ATEX-certified explosion-proof versions are available for specialized industry needs.

✔ Logistics Sorting Systems – Quick replacement of worn sections to improve maintenance efficiency

✔ Food Packaging Lines – Easy to disassemble and clean, compliant with hygiene standards

✔ Temporary Conveyor Systems – Ideal for exhibitions, construction sites, and other quick setup environments

✔ Automated Production Lines – Modular design facilitates equipment adjustments and upgrades

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;