- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

EN

EN

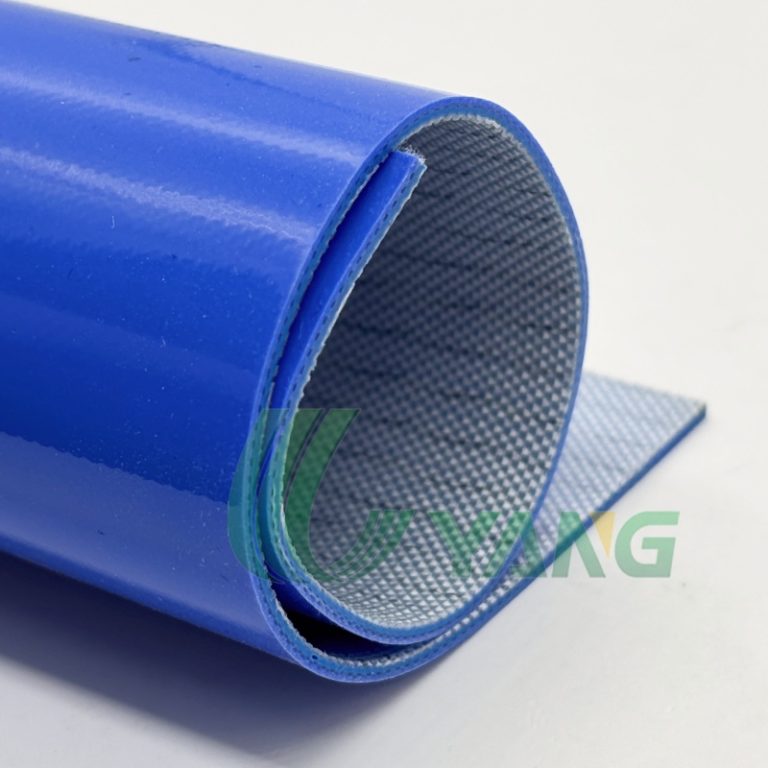

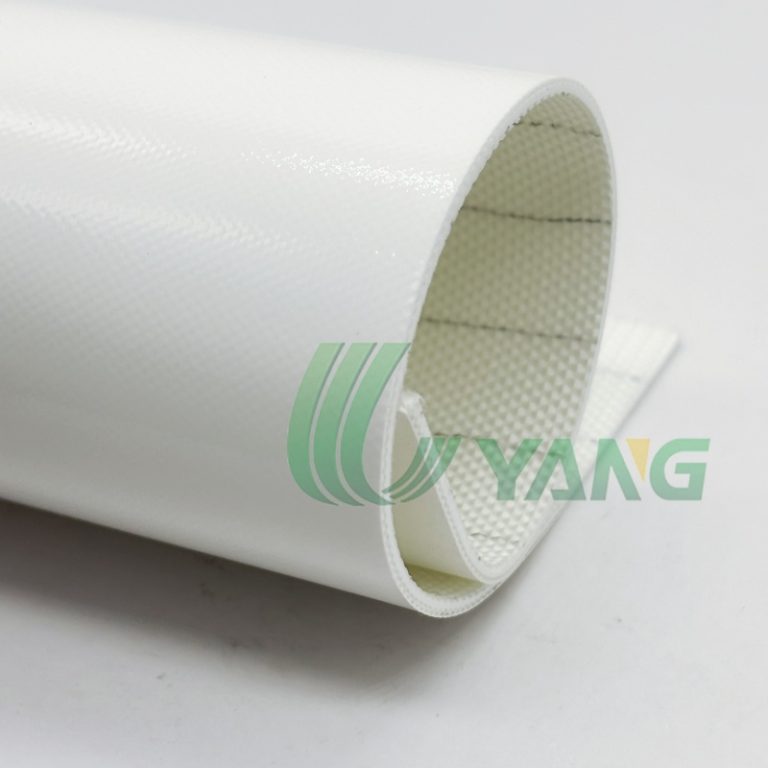

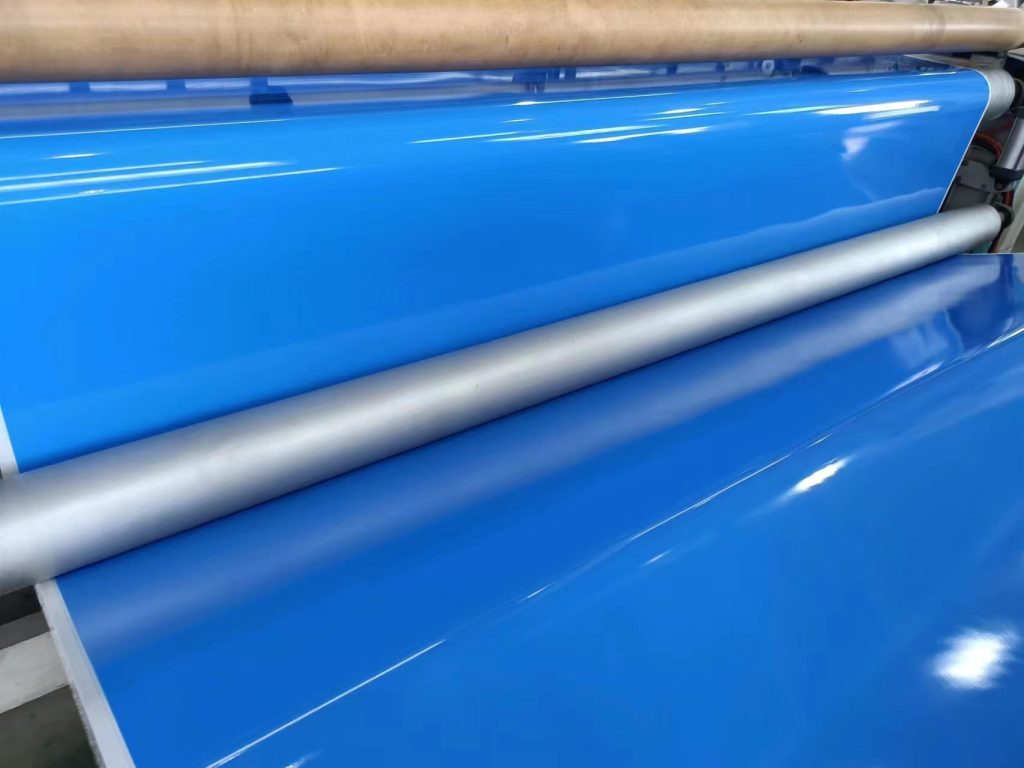

UYANG BELTING Silam belts are produced with polyester fabric as the bottom, PU as the middle layer, and covered on the surface with high-quality silicon compound of varying degrees of hardness; the surface will be anti-stick, and high hygienic level, oil resistant. The thickness, layers, and colors could be customized ; meanwhile, we could provide all different kinds of conveyor belt: PVC PU conveyor belt, Modular plastic belts, silicone belts, PVK belts, NOVO belts, etc; All could be customized as clients’ requirement.

UYANG BELTING Silam belts are produced with polyester fabric as the bottom, PU as the middle layer, and covered on the surface with high-quality silicon compound of varying degrees of hardness; the surface will be anti-stick, and high hygienic level, oil resistant. The thickness, layers, and colors could be customized ; meanwhile, we could provide all different kinds of conveyor belt: PVC PU conveyor belt, Modular plastic belts, silicone belts, PVK belts, NOVO belts, etc; All could be customized as clients’ requirement.

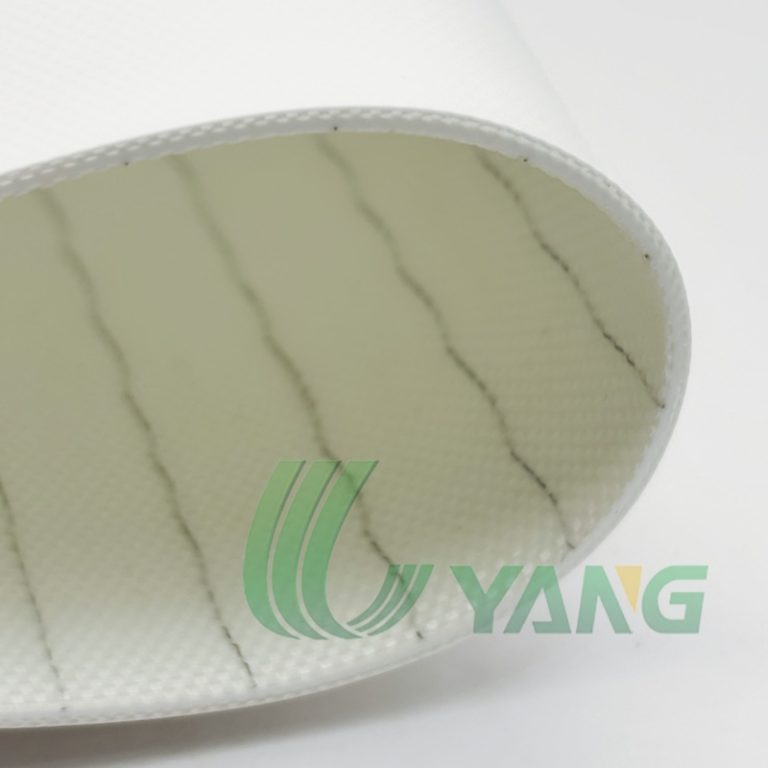

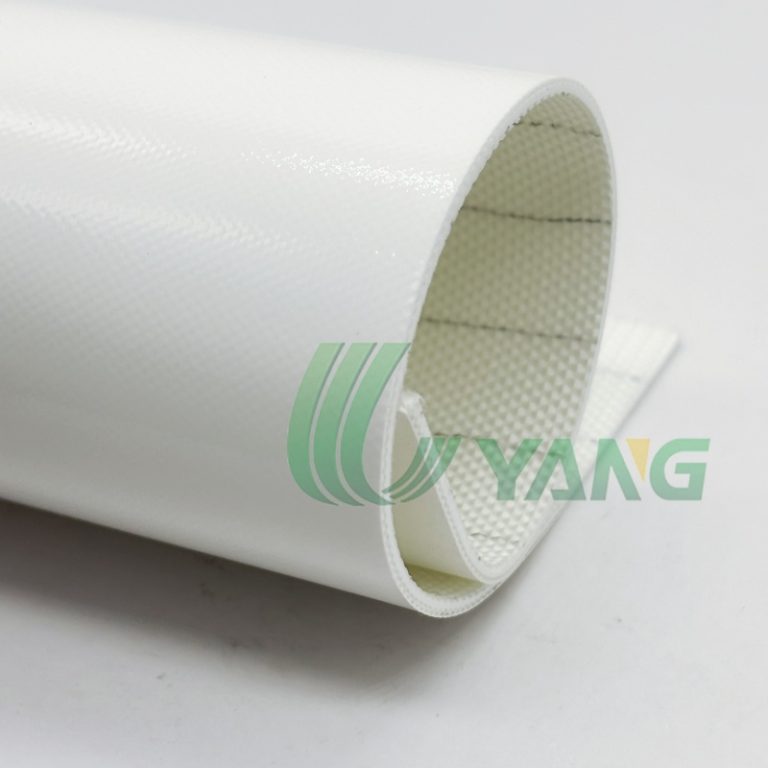

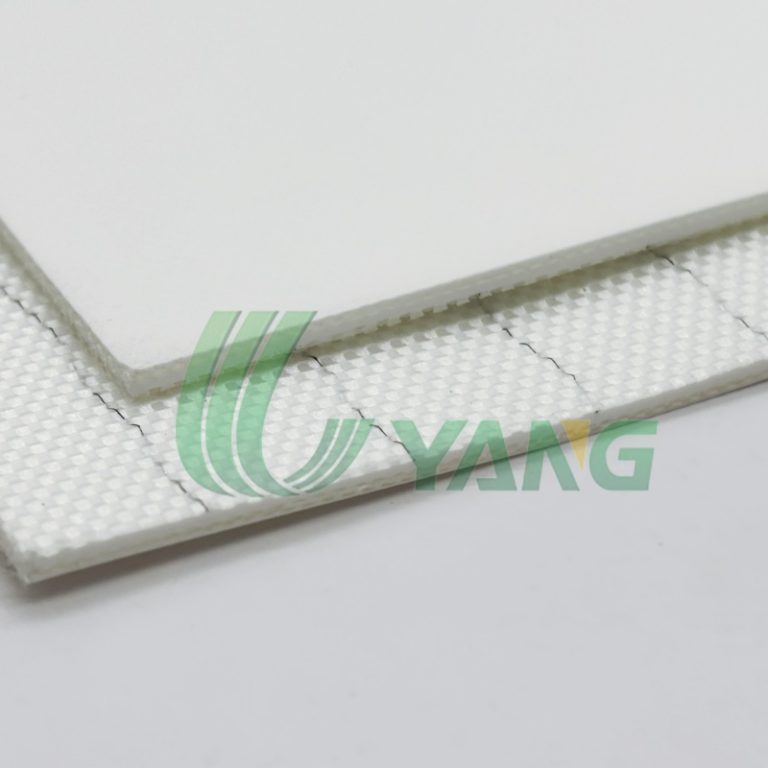

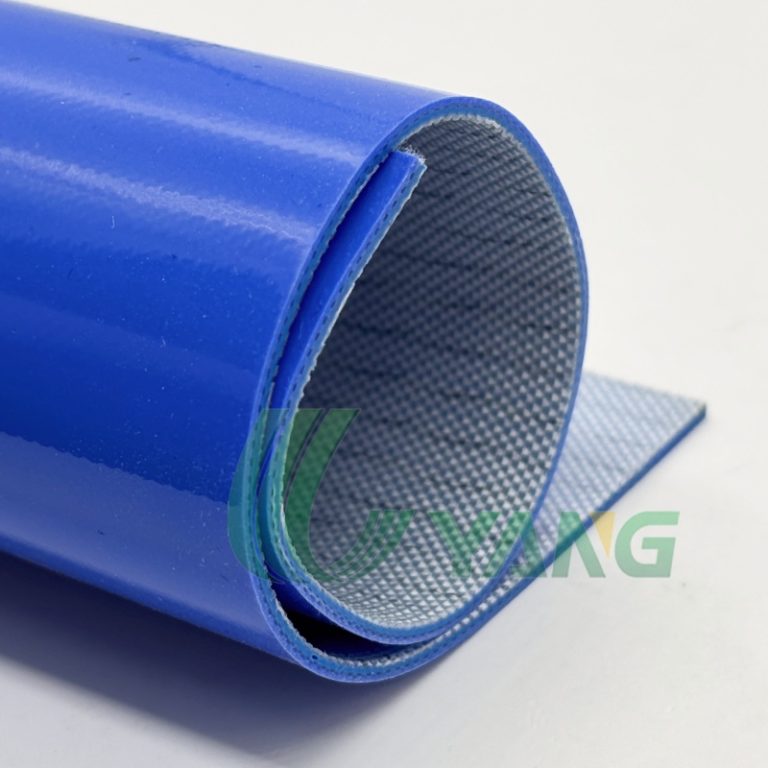

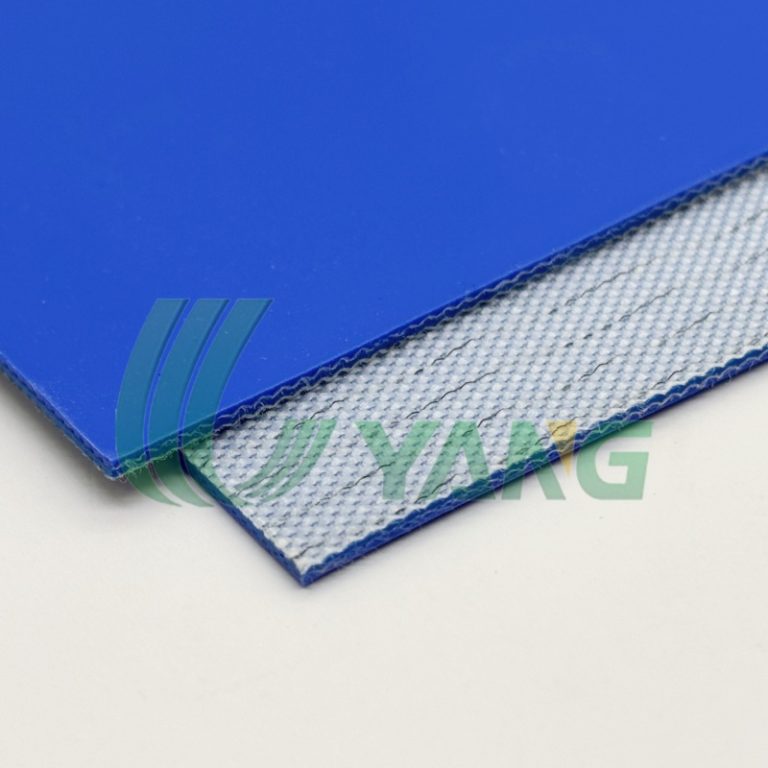

UYANG BELTING Silicone Conveyor Belt, also called “SILAM belts (silicone + PU):

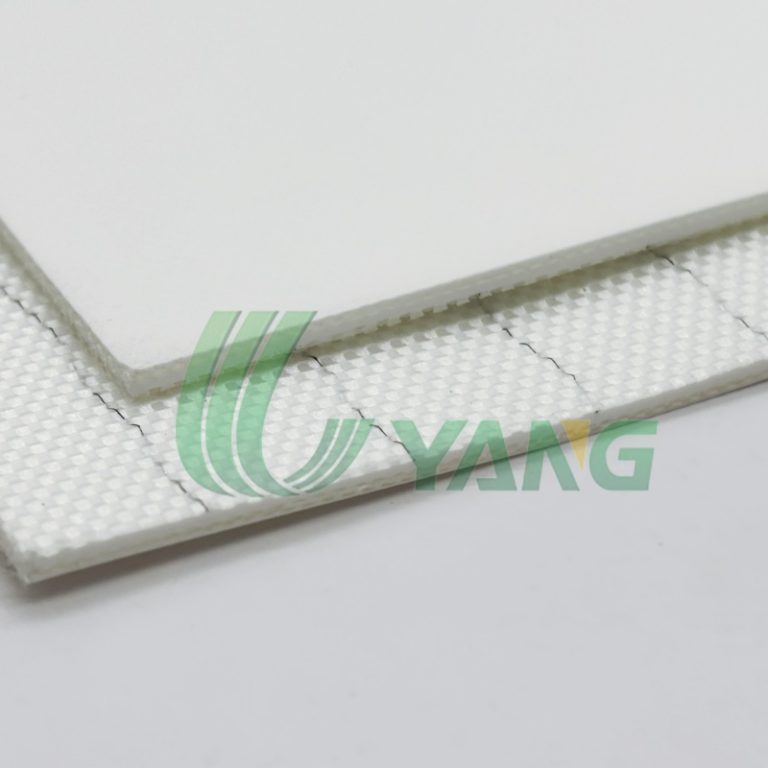

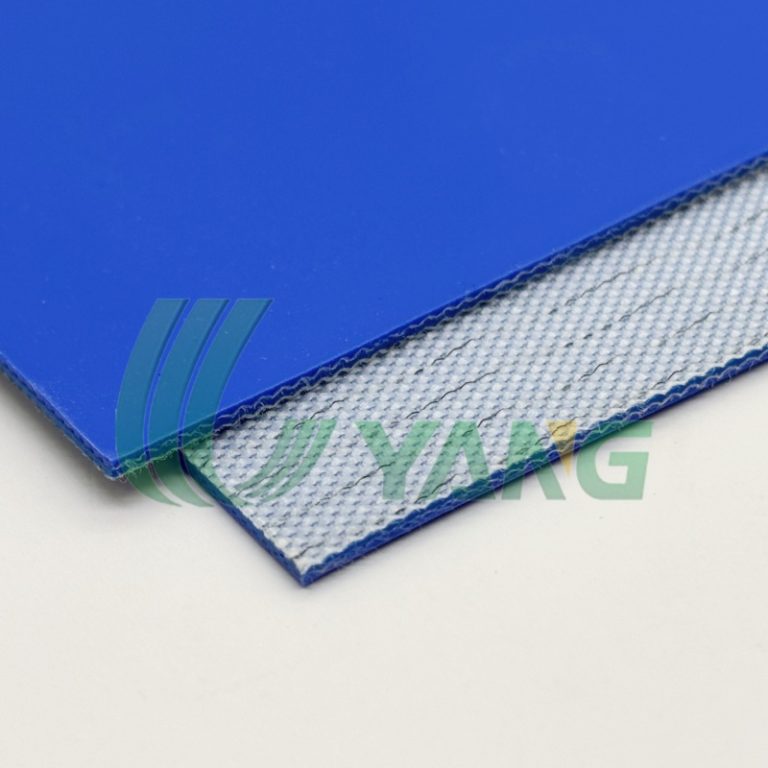

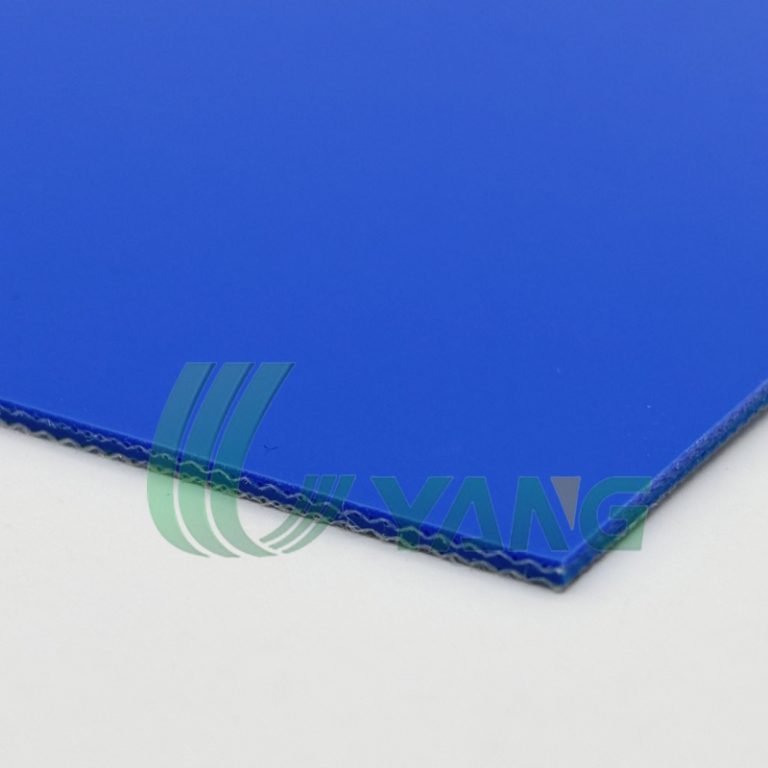

UYANG BELTING silicone conveyor belt features a structure with a thin layer of silicone on the surface, a PU layer in the middle, and a fabric layer.

Here’s a breakdown of its components:

The silicone surface layer primarily serves an anti-stick function.

It prevents materials from adhering to the belt, ensuring smooth material transfer along the conveyor line.

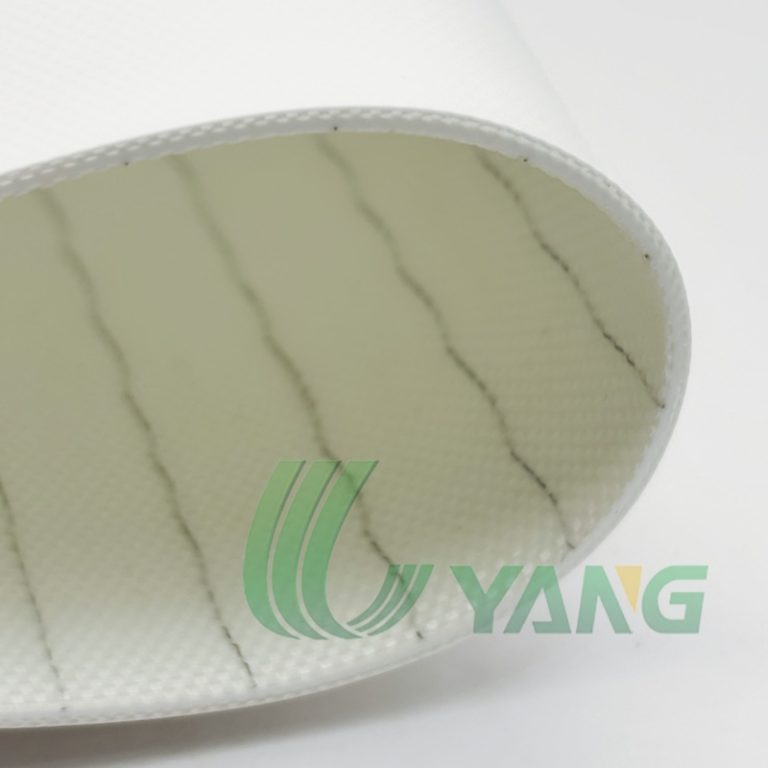

The PU middle layer provides the conveyor belt with good elasticity and flexibility.

This ensures smooth operation during usage, maintaining stability and reducing the risk of belt deformation.

Positioned between the silicone and PU layers, the fabric layer offers additional strength and support to the conveyor belt.

It helps prevent the belt from deforming or breaking during operation.

|

Product construction |

||

| Tension layer | Polyester, stable | |

| Number of plies | 2 | |

| Top side

|

Material | Silam, SI |

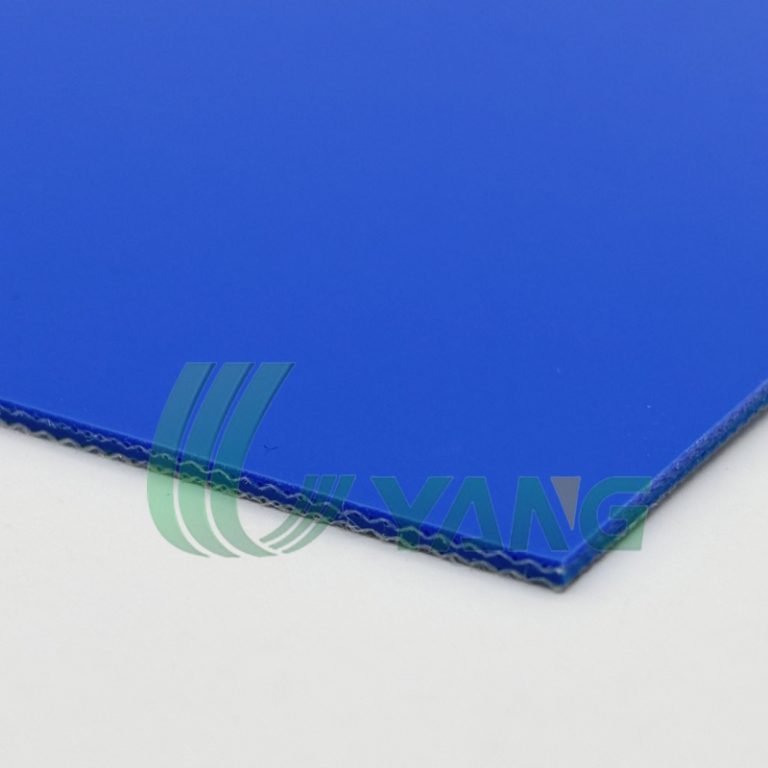

| finish | Smooth, Glossy | |

| color | white | |

| Bottom side

|

material | Ropanol, PUR |

| finish | Impregnated fabric | |

| color | transparent | |

|

Characteristics |

||

| Food Grade ( FG) | yes | FDA |

| Antistatic ( AS) | yes | ISO 21178 |

| High conductive (HC) | no | |

| Flame-retardant (FR) | no | |

| ATEX approval | no | |

|

Technical data |

||||

| -Hardness | ISO 868 | Top side | 30A shore | |

| -Force at 1% elongation | ISO21181 | 6 N/mm | 34.26 lbs/in | |

| -Thickness | total | 1.45mm | 0.06 in. | |

| Top cover | 0.2mm | 0.01 in. | ||

| -Weight | 1.5 kg/m2 | 0.31 lbs/ft ² | ||

| -Operating temperature | continuous | From / to | -15/90 °C | 5/194 °F |

| short | From /to | -15/110 °C | 5/ 230°F | |

| -Minimum pulley diameter | flexing | 6mm | 0.24 in. | |

| backflexing | 40mm | 1.57 in. | ||

| -Manufacturing width | standard | 2000mm | 79.53 in. | |

| maximum | 2000mm | 79.53 in. | ||

Application in the Food Industry:

This type of conveyor belt is commonly used in the food industry due to its anti-stick properties provided by the silicone surface layer.

It ensures hygienic material handling and prevents contamination, making it suitable for applications where food safety is a priority.

Overall, the silicone conveyor belt with a PU middle layer and fabric reinforcement offers reliable performance in the food industry, maintaining smooth operation while meeting hygiene standards.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;