- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

SW

SW

UYANG BELTING could provide many types of homogeneous belts, and we could provide the sidewall, guide, cleats which could add on the homogeneous belt to improve the effectiveness of the conveyor, and protect the goods from falling, and separate the goods to keep hygienic; We use advanced high-frequency welding technology to ensure a durable, hygienic bond for extended service life and reduced maintenance. On-site installation services are available upon request.

UYANG BELTING could provide many types of homogeneous belts, and we could provide the sidewall, guide, cleats which could add on the homogeneous belt to improve the effectiveness of the conveyor, and protect the goods from falling, and separate the goods to keep hygienic; We use advanced high-frequency welding technology to ensure a durable, hygienic bond for extended service life and reduced maintenance. On-site installation services are available upon request.

Purpose to add Guide on the bottom of belt:

Key Feature:

Improved Belt Tracking

Guide strips help the belt stay aligned throughout the operation, minimizing the risk of side drift or misalignment—especially important in systems with frequent starts, stops, or directional changes.

Extended Belt Life

By keeping the belt centered and reducing lateral stress, guide strips prevent edge wear and surface damage, helping extend the overall lifespan of the belt.

Enhanced System Stability

Easy to Clean and Maintain

A stable, well-aligned belt is key to a reliable conveying system—and that’s where guide strips come in. Designed to prevent misalignment and ensure smooth tracking, UYANG BELTING guide strips are the quiet heroes behind efficient belt performance.

Whether you’re running a compact conveyor or a large-scale production line, the right guide strip setup ensures your easy-clean belt performs at its best—every shift, every day.

Accurate Tracking

Guide strips help the belt stay centered during operation, reducing the risk of side slip or edge wear—especially important in high-speed or washdown environments.

Custom-Fit Design

We offer guide strips in various shapes and sizes to suit your belt width, system layout, and tracking needs. Whether you need a single center strip or multiple side guides, we’ll match the design to your setup.

Hygiene-Friendly Materials

UYANG BELTING guide strips are easy to clean, resistant to moisture and chemicals, and compliant with industry hygiene standards.

Low Wear, Long Life

With a smooth surface finish and tough construction, the guide strips are designed to minimize friction, reduce belt wear, and keep your system running longer with less downtime.

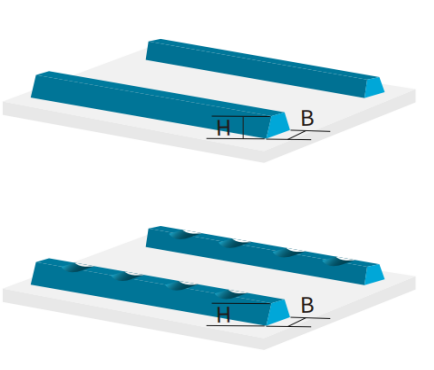

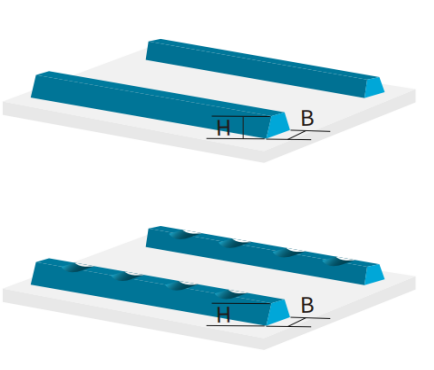

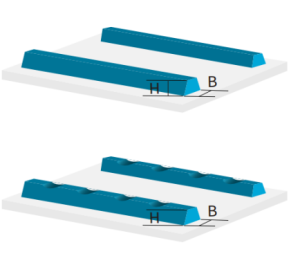

Guide Parameters

| Code | Rangi | Specification | Minimum roll diameter with teeth | Minimum roll diameter without teeth | Hardness | With teeth | |

| B | H | ||||||

| K5 | Blue/white | 5 | 3 | 25 | 30 | 70A | Available |

| K6 | Blue/white | 6 | 4 | 30 | 35 | 70A | Available |

| K8 | Blue/white | 8 | 5 | 35 | 45 | 70A | Available |

| K10 | Blue/white | 10 | 6 | 45 | 50 | 70A | Available |

| K13 | Blue/white | 13 | 8 | 60 | 70 | 70A | Available |

| K17 | Blue/white | 17 | 11 | 90 | 100 | 70A | Available |

| TK10 | Blue/white | 10 | 10 | 80 | 70A | ||

Note: The minimum roll diameter is the front parameter of the belt, and the C-guide can be customized

according to customer requirements

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;