- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

SW

SW

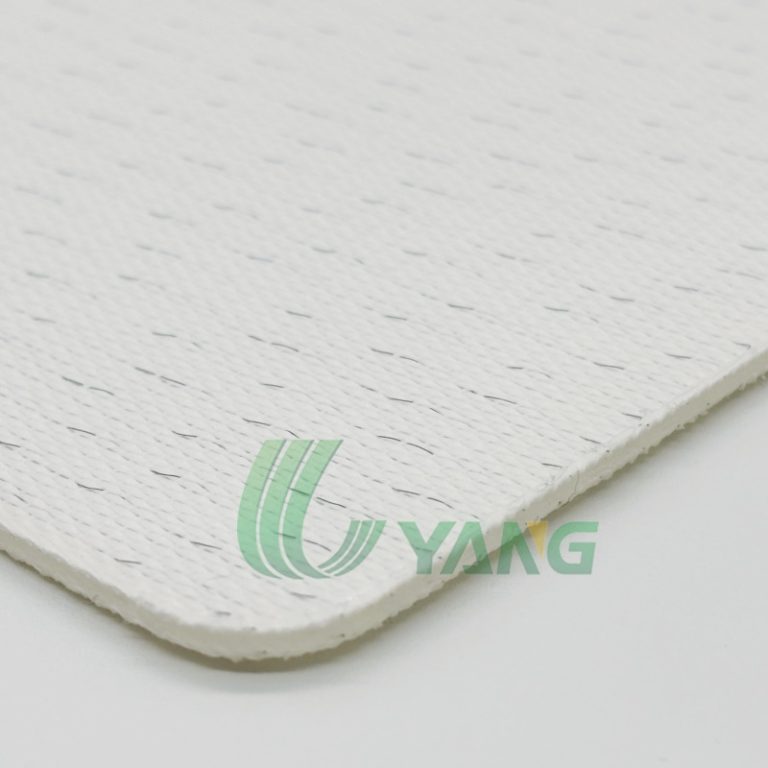

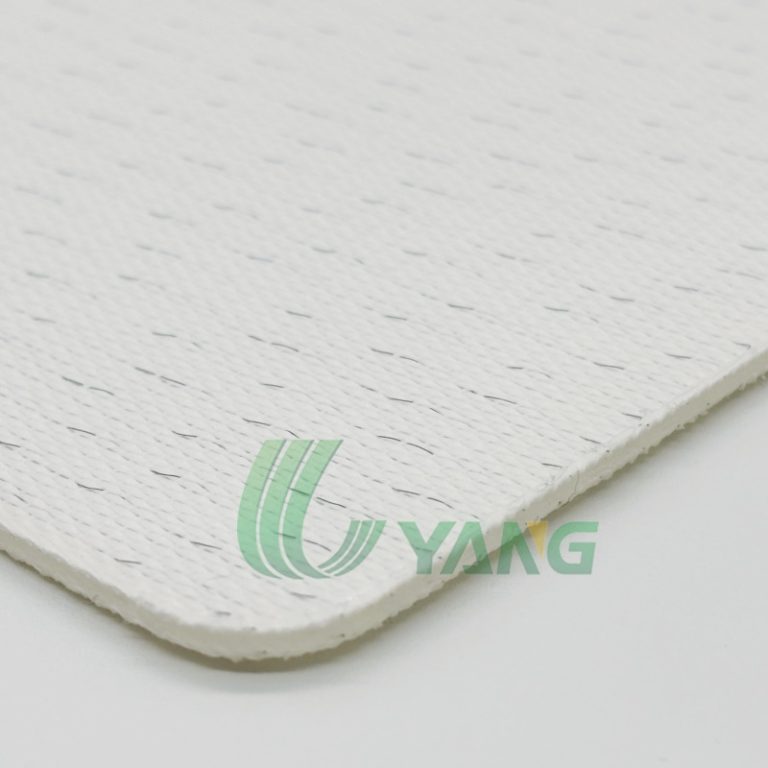

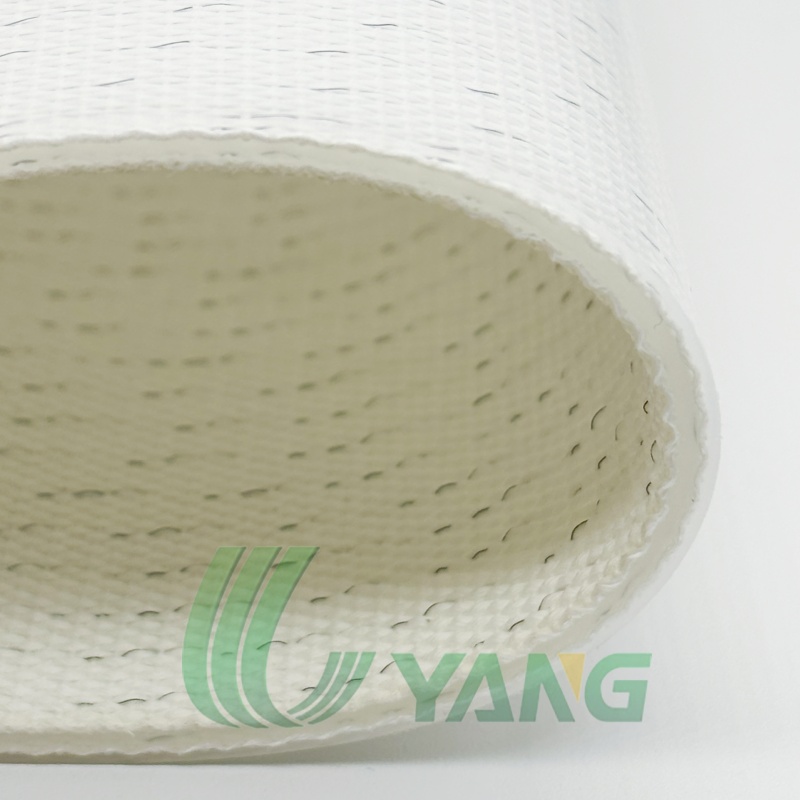

UYANG BELTING PE Conveyor Belts – Our textile-free polyethylene belts provide the ultimate hygienic solution with seamless smooth surfaces that prevent contamination while offering exceptional cold resistance down to -73°C for frozen food and pharmaceutical applications. The ultra-clean design combines chemical resistance with easy sanitation, making them ideal for contamination-sensitive industries requiring reliable low-temperature performance.

UYANG BELTING PE Conveyor Belts – Our textile-free polyethylene belts provide the ultimate hygienic solution with seamless smooth surfaces that prevent contamination while offering exceptional cold resistance down to -73°C for frozen food and pharmaceutical applications. The ultra-clean design combines chemical resistance with easy sanitation, making them ideal for contamination-sensitive industries requiring reliable low-temperature performance.

Key Advantages:

✓ 100% Textile-Free Construction – Eliminates fiber shedding and edge fraying for contamination-free operation

✓ Seamless Smooth Surface – Non-porous design prevents bacterial growth and allows easy cleaning

✓ Extreme Cold Resistance – Maintains flexibility down to -73°C for frozen food and cryogenic applications

✓ Superior Chemical Resistance – Withstands acids, alkalis and cleaning detergents

UYANG BELTING PE conveyor belts provide the ultimate contamination-free solution with their textile-free construction, eliminating edge fraying risks. The non-porous surface ensures superior hygiene with easy cleaning and inherent bacterial resistance, while premium PE material offers exceptional detergent compatibility.

Specially formulated for extreme cold operations, these belts maintain flexibility down to -73°C with outstanding impact resistance – making them perfect for:

✓ Frozen food processing (ice cream, seafood)

✓ Cryogenic material handling

✓ High-impact packaging lines

Key Material Advantages:

• Chemical-proof: Withstands acids/alkalies

• Shock-absorbing: Unmatched low-temperature durability

• Lightweight flexibility: Low friction energy efficiency

Technical Data:

| Aina | Plies | Rangi | pattern | Total Thickness

(mm) |

Cover thickness

(mm) |

Cover hardness

(mm) |

Weight

(kg/m2) |

Effective pull at 1% elongation

(N/mm) |

Breaking Strength

(N/mm) |

Min Dia

(mm) |

Counter Flexion |

| 13E11-09/oA | 1 | Transparent | Matt | 1.3mm | 0.3/0.3 | 90 | 1.6 | 6 | 60 | 30 | 30 |

| 21E23–04/OHA | 2 | Transparent | Matt | 2.1mm | 0.5mm | 90 | 2.5 | 14 | 200 | 80 | 100 |

| 36E33-04/OA | 3 | Transparent | Matt | 3.6mm | 0.3mm | 90 | 4.3 | 15 | 250 | 120 | 150 |

| 50E21-06/27 | 2 | Transparent | Staggered Stud | 5.0mm | 3.0mm | 90 | 4.4 | 14 | 200 | 80 | 120 |

Need a belt solution for your hygienic or cold-environment application?

Our PE conveyor belts provide the perfect combination of cleanliness and durability.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;