- HOME

- PRODUCTS

- INDUSTRIES& APPLICATIONS

- ABOUT

- CONTACT

UR

UR

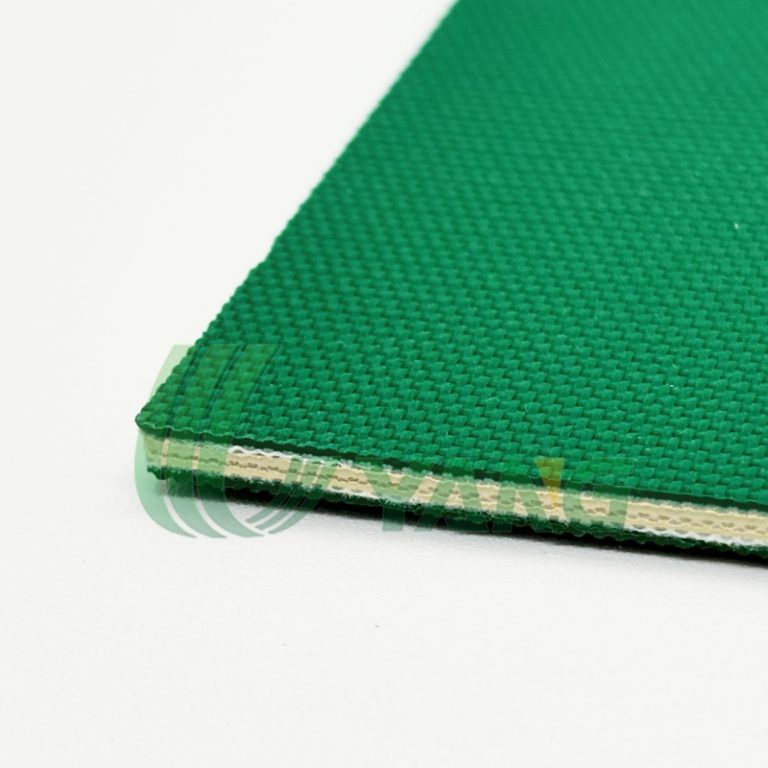

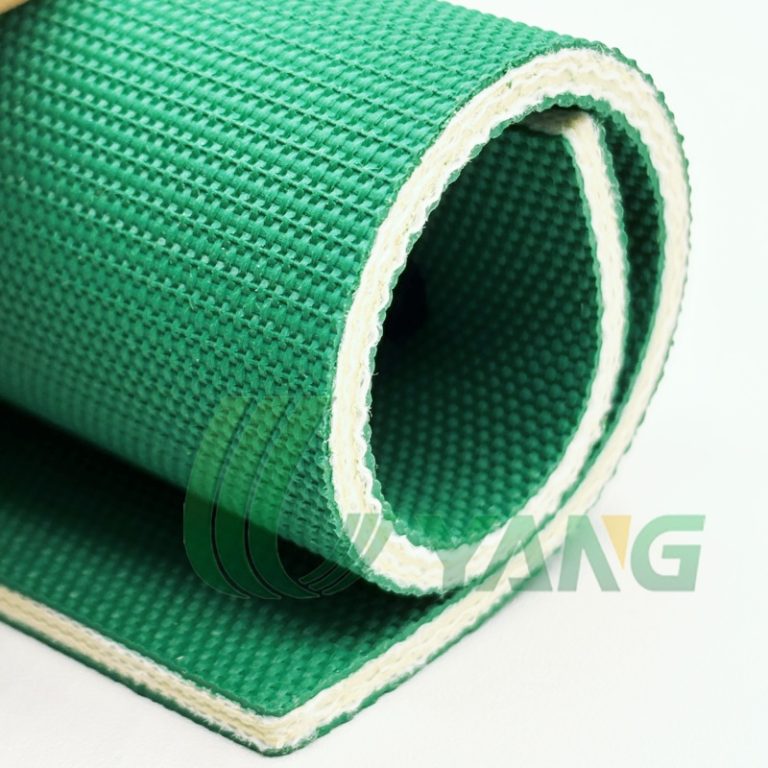

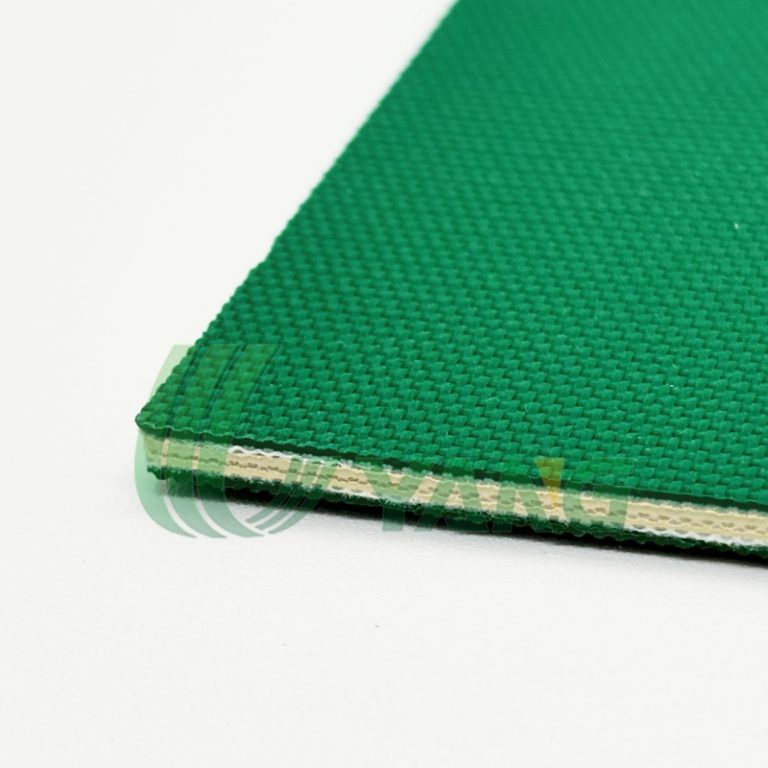

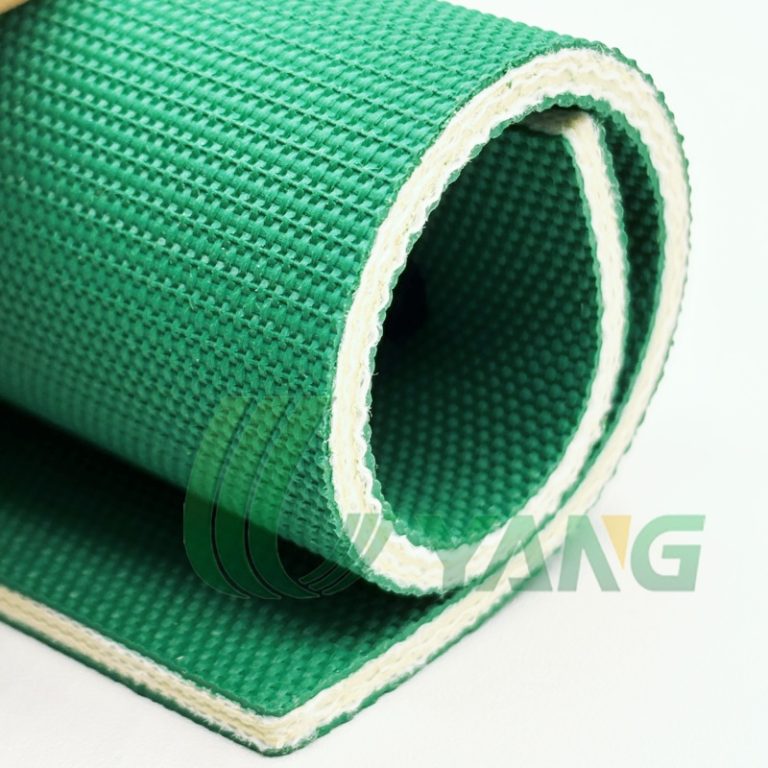

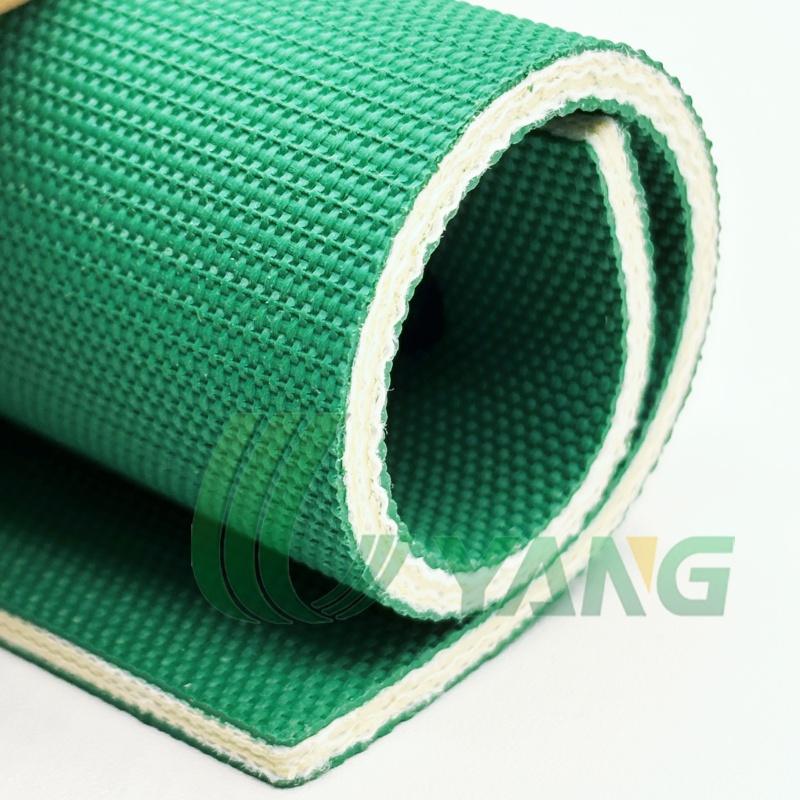

UYANG BELTING Green Nitrile Rubber Belt is designed with a double-sided coarse texture pattern, offering excellent grip, wear resistance, and flexibility. With a reliable and stable conveying solution tailored for shoemaking machinery. Green appearance and double coarse texture surface deliver effective material handling, especially for shoe components during the gluing, forming, and pressing processing. Made from high-quality NBR (nitrile rubber), it is also oil-resistant and anti-slip, making it ideal for production environments with frequent exposure to adhesives and lubricants.

UYANG BELTING Green Nitrile Rubber Belt is designed with a double-sided coarse texture pattern, offering excellent grip, wear resistance, and flexibility. With a reliable and stable conveying solution tailored for shoemaking machinery. Green appearance and double coarse texture surface deliver effective material handling, especially for shoe components during the gluing, forming, and pressing processing. Made from high-quality NBR (nitrile rubber), it is also oil-resistant and anti-slip, making it ideal for production environments with frequent exposure to adhesives and lubricants.

Shoemaking Machines – Gluing machines, pressing lines, automatic conveyors

Footwear Assembly Lines – Especially for sports shoes, leather shoes, safety shoes

Light Industrial Conveying – Where good friction and oil resistance are required

| Item | Details |

|---|---|

| رنگ | Green |

| Material | NBR (Nitrile Rubber) |

| Top Surface | Coarse Texture Pattern |

| Bottom Surface | Coarse Texture Pattern |

| Structure | 3 Ply Fabric / 4 Rubber Layers |

| Total Thickness | 3.0 mm |

| Key Features | Anti-slip, oil-resistant, flexible, durable |

| Application Focus | Shoe manufacturing, light-duty industry |

✅ Double-Sided Coarse Texture

Provides consistent friction and stable product positioning on both sides, ideal for the precise handling of shoe parts during production.

✅ 3 Ply / 4 Rubber Layer Construction

Ensures durability and strength while maintaining flexibility for smooth operation around pulleys and rollers.

✅ NBR Rubber Compound

Excellent resistance to glue, oils, and mild solvents, commonly found in the shoemaking process.

✅ Lightweight & Flexible (3.0mm Thickness)

Designed for compact or small-radius conveyor systems, offering reduced energy consumption and reliable belt tracking.

✅ Green Color Design

Visually distinguishes the belt from other materials, improving line visibility and safety in fast-paced production environments.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;